Operating principle and design

A water-jet propulsion unit, or simply a water jet, is a propulsion device (a special device that converts the energy of an external source or engine, by interacting with the environment, into the process of moving transport), whose force, which imparts movement to a sea vessel, is formed by a water jet that is pushed out of him.

Essentially, a water-jet propulsion unit is a water-type pump that operates in underwater space.

The principle of operation of the device resembles the method of movement of some mollusks (octopuses, jellyfish, etc.). These types of sea creatures move by throwing out the water they take in.

Water-jet propulsors have four main components in their design:

- an impeller, or screw having a shaft;

- water pipeline;

- straightening apparatus;

- reverse steering type device.

The conduit is a profiled pipe in which the flow of water becomes faster either due to a blade-type mechanism, or due to the energy of fuel combustion, or due to compressed gas pressure. The latter system facilitates the directed movement of the string through the outlet located in the aft area. The water mass, thrown back by a sharp impulse, creates the main thrust of the engine, and this in turn forces the vessel to move on the surface of the water.

Water conduits are located in the interior of the hull of any water-jet outboard boat or jet-propelled boat. How effective a water jet engine can be depends mainly on what shape the water pipes have, where they are located and what design the water intakes have.

The RRU, during rotational movements in the horizontal flow plane, causes the vessel to turn. If the flow is blocked directly from the nozzle, the water jet turns in the opposite direction, giving the vessel a reverse motion.

The water jet quite often becomes clogged with seaweed. When they wrap around the impeller and shaft, the mechanism may jam. For such cases, in order to avoid system breakdown, water-jet boat engines are provided with a special key on the surface of the shaft. You can open a small hatch to remove all algae.

How to create an engine yourself?

Creating an engine with your own hands is not as difficult as it might seem at first glance. Jet propulsors are usually made by fishermen based on the classic type engine design. The future product may be based, for example, on Chinese or domestic engine models (from 5L to 100L). Drawings of these structures are presented in the following form:

To make a water jet motor, you can use a classic standard gearbox: it must be attached to the main deadwood in the engine area. This is achieved by using a flange. After this, a metal blank is taken, where the design of the water intake, 6 blades and the water intake should be assigned.

To create a workpiece based on a standard design, a file and rollers are used. Afterwards, using the same tools, the product is processed. As a result of the work done, the workpiece receives the required shape. After this, the moment comes to weld the seams of the longitudinal and transverse types.

The water-jet structure must also acquire a hub: an area is allocated for this part in the location of the boss. The boat pump in its dry structure weighs twenty kilograms. However, the pattern of this product may occur in very rare cases. However, anyone can make a pump on their own, since there is quite a sufficient amount of instructional materials on the global network. It is also important to take into account that jet boats have a greater degree of profitability than boats with a simple engine.

Jet outboard motors for inflatable boats are much easier to manufacture than for large boats with a jet engine. The main advantage is that almost any type of motor can be used for this type of boat, regardless of design. It is recommended for them to choose water-jet propulsors, the power of which ranges from fifteen to twenty hp.

The most suitable motor option for a boat is considered to be an outboard motor. Compared to a stationary motor, an outboard jet boat motor does not cover the useful volume of the boat and is easily dismantled. The device is characterized by low weight, high level of UM, simple design, and ease of use.

Positive and negative features

Water-jet propulsors are characterized by the following advantages:

- a good degree of protection from mechanical damage, as well as the ability to prevent cavitation;

- the vessel can pass through shallow water, overcome ponds that have become clogged, as well as other types of obstacles that protrude from the water. Water-jet propulsors here turn out to be more optimal than simple screw-type motors, in which the propeller or main motor may suffer;

- safety guarantee - the impeller is located in the inner part of the product and does not pose a danger to those people who are near the boat;

- water-jet outboard motors provide boats with greater stability and excellent controllability;

- water jet propulsion allows the boat or boat to turn right on the spot, as well as move forward on its side;

- the need to use reverse disappears, there is the possibility of sharp braking;

- lower hydrodynamic noise than that of screw propulsors.

- efficiency at low speeds is less than that of screw systems;

- the difficult process of transferring the water mass through the bottom of the water transport to the pump itself;

- the water intake functions like a pump, drawing in small debris from the bottom. Because of this, the cooling system may become clogged or the water pipe, as well as the impeller, may be damaged;

- high probability of rotor wear, because the vessel is operated in shallow water areas;

- expensive repairs;

- A jet boat can act up when moving slowly.

Choosing a water jet

When selecting a product of this type for a boat or boat, you must have information regarding 3 basic components of a watercraft:

In relation to the propulsion, these are traction characteristics, which depend on the degree of power of the engine itself, as well as on how fast the ship is moving.

In relation to the engine, this is a characteristic of the speed of the external sample, a dependent relationship between the power of the engine itself and how quickly it makes movements.

In relation to the hull of the boat itself, there is resistance of the towing type, a direct dependence of the resistance of the hull on the speed at which it moves. These types of characteristics can be calculated in the case of varied ship loads.

Important information about water cannons

Jet outboard motors are by no means an ideal way to navigate shallow water.

It is worth remembering that, along with water, sand, small debris and other particles can be drawn into the cooling system, the impeller or water pipe.

If you constantly walk in shallow water, the rotor and starter may wear out.

Well, due to the suction of a certain volume of water, the total weight of the vessel increases, so you should not expect easy access to planing mode from these engines.

If we compare water-jet outboard motors with amphibious vehicles, they are similar to all-terrain vehicles.

Jet engine design

The main elements of such a mechanism, as in the classic version, are the internal combustion engine and the propeller, only the latter is located inside a long pipe laid along the hull of the boat. Of course, “pipe” is an oversimplified term. The correct name for this part of the engine is the water conduit, and it consists of the following components:

- water intake: the front part through which water flows to the propeller;

- straightening apparatus: thanks to this element, the rotational movement of the water flow twisted by a screw is transformed into a rectilinear one;

- nozzle apparatus: the final part of the “pipe” from which water is thrown out.

Another important element of the water cannon is the reversible steering device, thanks to which the boat can change the direction of movement and also reverse.

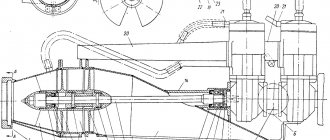

Water jet engine design diagram

Screws (also called impellers or impellers) come in several types:

- Axial: the simplest to manufacture, but they provide the lowest efficiency and, due to the pronounced cavitation effect, can only operate at low speeds.

- Axial-diagonal: have higher efficiency and are designed for medium-speed engines;

- Diagonal and screw: the most modern and extremely difficult to manufacture varieties, they are characterized by the highest efficiency and are capable of working with high-speed engines.

Among all the components of a water cannon, propellers are in first place in terms of manufacturing complexity. For this purpose, the method of precision casting followed by grinding is used.

You should not purchase a water cannon with an impeller whose blades are welded to the hub and do not form a single whole with it: such propellers often have an imbalance, which leads to their destruction at high speeds.

Hydrojet propulsion or electric “water jet”

An electric water jet is an engine and a power plant: two in one device, a project of the Italian startup DeepSpeed. It is designed similarly to a rim engine: only the blades are attached not to the central hub, but to the rim of the housing, and water flows through the middle.

If you compare DeepSpeed with propellers and conventional water jets, the advantages are obvious. Firstly, mechanical losses during its operation are practically reduced to zero: there are no gears, shafts or universal joints transmitting power from the engine to the drive, but only a pair of wires carrying current from the batteries.

Secondly, the compact and lightweight body, which weighs only 75 kg (without battery), takes up much less space than the engine and fuel tank. Thirdly, unlike a propeller, the efficiency of which decreases with increasing speed due to cavitation and losses, in DeepSpeed, due to the powerful energy of the jet, the efficiency and energy efficiency of boats increases.

DeepSpeed integrates a jet turbine, battery and control electronics, as well as an on-board power generation system. Thus, Sealence plans to produce power plant kits for the modernization of ships equipped with gasoline or diesel engines.

The business history of the “hydraulic water cannon” was born in the summer of 2007 from what seemed to be a joke. That's when the sports motorboat of William Gobbo, the startup's current CEO and thought leader, broke down. The invoice of 20,000 euros for the repair of an old US 8-cylinder engine that came by email was puzzling. “With this money,” William joked in a conversation with friends, “I’d rather install an electric motor and save on gasoline.”

A little later, inspired by the idea, he made a computer model of the installation, and the first working prototype was released in 2010.

But only in 2021 the idea received scientific confirmation and became real. Ernesto Bennini, one of the world's leading experts in hydrodynamics and jet engines, joined the project.

The 2021 DeepSpeed prototype is similar to the body of a jet aircraft engine because, like a turbofan engine, it is designed to force water (rather than air) into the front, accelerating it through a smaller exhaust nozzle. The rotating blades of a single-stage impeller generate thrust, providing greater speed with less energy loss at high speeds.

The faster the boat goes, the more water is fed into the jet, increasing its overall efficiency. Because the jet engine is located outside the hull rather than inside it, there is less noise and vibration transmitted through the hull. In addition, such a device does not require an additional cooling system - its efficiency is ensured by the incoming flow of water.

Some boat manufacturers are already considering options for installing DeepSpeed jet propulsion on newly developed or existing boat designs when upgrading them.

Amer Yachts and Scanner Marine announced back in April 2021 that they were working on installing DeepSpeed electric hydropropulsion engines on their Envy 710 RIB.

Northrop B-2A Spirit stealth strategic bombers at the 509th Whiteman Wing base in Missouri Photo: https://www.taringa.net/posts/imagenes/18143532/Northrop-Grumman-B-2-Spirit-Mix-de -fotos.html

New DeepSpeed DS-780 powerplant with 680 hp. and a torque of 1500 N • m. It has a peak thrust power that is equivalent to a fairly “voracious” internal combustion engine. It is expected that the model will be most effective in the speed range from 16 to 26 knots on semi-planing yacht hulls. Another powerful but smaller powerplant, the DS-420, is designed for fast boats with an expected power rating of 300 hp and 560 Nm of torque.

Looking ahead, Sealence plans to bring to market a complete package of hybrid and electric propulsion systems, with a modular lithium-ion battery system, solar panels, a diesel backup power generator and an expanded line of DeepSpeed propulsion systems controlled via Smartbox. Today these are boats with a length of 9 to 24 meters.

The story about the DeepSpeed project would be incomplete without mentioning the story of how the startup found 3 million euros of investment. On the crowdfunding platform, the funds necessary to launch the startup were collected in two stages. The success is impressive and easy to explain. Italian engineers presented an interesting and real working project. The team’s scientific research, constant testing of the startup, and improvement of the product, which is produced by a private company without much government support, command respect.

Found a typo? Select a fragment and press Ctrl+Enter.

Tags: Technologies hydrojet water jet Engine GE9X propulsion electric motor

Previous article Unique synthesized materials for use in aircraft engines have been developed in Russia

Next article Safran helicopter engine runs on 100% aviation biofuel

Provided by SendPulse

Likes 0

- 0

- 0

- 0

- 0

Advantages and disadvantages

By installing a jet engine, the owner of the watercraft benefits from the following:

- Since the propeller hidden in the conduit is not in danger of being wound up by algae, the boat acquires the ability to easily move through overgrown reservoirs.

- Impacts of the propeller on the bottom are also eliminated, which makes it possible to swim unhindered in places with shallow depths or shallows.

- A boat with a water jet becomes safe for swimmers, divers and fauna living in water bodies.

- Unlike conventional propellers, water jet impellers, especially modern ones, are protected from the negative effects of cavitation.

But you will have to come to terms with some disadvantages:

- With the same engine power, the boat will move slower than with a conventional propeller.

- Controllability deteriorates.

In addition, the boat becomes heavier due to the weight of the water filling the jet.

In order to change the pipes in the apartment, it is not necessary to call a team of craftsmen. Replacing pipes in an apartment with your own hands will significantly save money despite the complexity of this enterprise.

How to properly connect a toilet to a sewer pipe, see here. Overview of the main options.

Low water pressure in an apartment is not that uncommon. If the water utility cannot correct the situation, use our advice: https://aquacomm.ru/cancliz/mnogokvartirnyie-doma/santehnika/kak-uvelichit-napor-vody-v-kvartire.html. Ways to increase water pressure - from replacing pipes to installing a pumping station.

Homemade water jet for PVC boat

Compared to volumetric boats, PVC boats are considered the most practical and compact. In the event that they require the installation of water jet equipment.

Since almost any model of boat engines is suitable for vessels of this type. Therefore, if the boat develops up to 20 horsepower, then this will be quite enough.

In the city markets you can find absolutely any design, so there should be no problems with its acquisition. So you can buy parts based on your taste.

It is not recommended to use heavy motors, so when creating a model of equipment it is important to pay attention to lightweight designs

In most cases, it is better to take parts from imported manufacturers, since products from Russian manufacturers are considered to be of lower quality.

Materials for production:

- Engine.

- Gearbox equipment.

- Iron disk, with slots for bolts.

- Part for fastening the chassis.

- Welding device.

- Water collector assembly diagram.

- Drawing materials.

- Fittings for connecting parts.

- Mixture for gluing.

Preparation

The most crucial moment in the manufacture of a motor is its clearly thought-out production scheme. Since the slightest inaccuracy can lead to an emergency.

After each connection of parts, it is important to double-check the quality of its fastening, based on the data of the made layout. At the same time, every action must be taken into account; this work is very responsible.

Manufacturing

The width of the main opening of the water cannon for collecting water should have a slightly smaller circumference compared to the outer inlet of the pipe.

In some cases, in places with a very shady bottom, while swimming, the engine may slow down slightly due to grass getting into the engine compartment.

This is why such places should be avoided.

Installing a professional cleaning device for boat engines is not necessary; in this case, ordinary filters are quite suitable.

If you initially decided to create an artificially created water cannon, then in order for it to serve for several years, first of all, you do not need to take on the first motor construction scheme that comes your way, it is important to watch all the necessary video and photo materials, as well as chat on forums with people who know production technology. The main part of the engine's operation lies in the position of the propeller

It is important that it is placed in accordance with the dimensions of the engine compartment itself.

The main part of the engine's operation lies in the position of the propeller

Read Fishing with a feeder - Tactics

It is important that it is placed in accordance with the dimensions of the engine compartment itself. In general, PVC boats are not high-speed vessels, so they use low-power motors compared to boats

Which will be quite sufficient for river walks and for fishing

In general, PVC boats are not fast vessels, so they use low-power motors compared to boats. Which will be quite sufficient for river walks and for fishing.

By creating your own design, you can end up with a very effective and high-quality item. It is possible that it will turn out to be much better and more profitable than the factory one.

Principle of operation

Throwing water out at high speed, the water cannon creates jet thrust, which sets the boat in motion. Let's look at this process in more detail:

- Water enters the water intake located at the front of the boat. It is equipped with a mesh that filters out algae and debris floating in the water. When designing a water intake, engineers strive to ensure laminar flow of water in it, since the presence of turbulence on the approach to the propeller significantly worsens engine performance.

- The propeller throws the water back with force, while it enters the narrowing, due to which its speed increases.

- The straightening apparatus, as already mentioned, increases the flow speed by converting its rotational motion into translational motion. They try to give its blades a shape that would provide the least resistance to the moving fluid. Manufacturers use various designs of straightening devices. One of them - blade preload - allows you to use this element simultaneously as a nozzle apparatus.

- Next, the flow enters the nozzle (if this function is not performed by a straightener). Due to the small flow area, water pressure here is converted into speed - this effect is called compression.

Water cannon operation diagram

PERFORMANCE

The power of the jet stream can be compared with the power removed from the propeller shaft. The design of a high-speed water jet propulsion system is limited by the load-bearing capacity of the jet. To increase draft, more water must be supplied at higher pressure. However, the power of the engine itself is limited to the same amount of engine horsepower, and the main concept when assessing the power of a water jet is jet thrust. This can be compared with the choice of the diameter and pitch of a propeller, when with the same engine power in horsepower, the power of a boat motor can vary depending on the parameters of the propeller. An increase in the jet thrust of a water jet due to a narrowing of the nozzle capacity leads to an increase in the power of the boat motor, but also reduces the speed of the boat. The jet nozzle was not designed to achieve maximum boat speed, but rather average speed with a reasonable load. However, speeds of 80-90% of the speed of the boat on a motor with a propeller were achieved. This loss of speed is outweighed by the boat's ability to navigate ankle-deep water - areas that are inaccessible to propeller-driven motors. Water jets are much less susceptible to damage from underwater collisions and are easier to maintain. Only the shaft bearing needs to be lubricated periodically through grease nipples during maintenance of the jet nozzle.