How to repair a broken spinning rod

In order to repair a spinning rod with your own hands, you must first prepare the tools and materials:

- sharp painting knife;

- gas-burner;

- lighter;

- pliers;

- small file;

- sandpaper size 1000;

- cloth for metal;

- pieces of carbon fiber rods of various lengths and diameters for repairing a spinning rod knee that is damaged or broken;

- adhesives - waterproof PVA, epoxy, “Super glue” gel, for fixing bandages, guide rings, and repairing handles;

- waterproof clear varnish;

- nylon thread for fastening the installed access rings to the form, masking the place where the spinning rod broke;

- set of pass rings;

- corks from wine or champagne bottles.

Having prepared everything you need, you can repair both the failed last pass ring and the broken form near the butt.

Form repair

In modern two-piece plug spinning rods made of high-modulus graphite, the following types of breakdowns occur:

- cracks or breaks of the first (butt) leg of the spinning rod;

- cracking or breaking of the upper leg.

Repairing the form in both cases does not require significant expenses. It consists of the following steps:

- We inspect the rod at the point of breakage for longitudinal cracks. If they exist, the knee cannot be repaired - under load, the crack will inevitably increase in length and lead to complete failure of the entire knee.

- If no cracks are found, use a metal blade to trim the edges of the damaged knee.

- From old, but not split graphite knees from another broken fishing rod, we select and cut out a piece 10-15 cm long, which fits tightly inside the parts of the broken knee - a scupper.

- If necessary, grind the piece a little with sandpaper and a fine file.

- We insert the scupper into one of the parts of the repaired knee, so that it fits tightly inside it by 7-8 cm. We generously lubricate the edge of the knee and the scupper inserted into it with epoxy glue. When repairing the butt knee, the scupper can be passed inside it by removing the plug located at the end of the handle after the spinning reel seat.

- We insert the second end of the spigot inside the other part of the broken knee so that the gap between the two joined parts of the broken knee is minimal.

- Cover the joint with epoxy glue.

- We wind a thin nylon thread over the connection, trying to match its color to the tone of the form coating.

- We cover the nylon thread bandage with waterproof varnish.

- If one of the rings of the spinning rod is very close to the place of breakage, then to strengthen the blank and disguise the bandage, remove it and fasten it above the junction of the broken parts of the knee with nylon thread.

- If the breakdown affected the varnish of the spinning rod rings or damaged the winding that attaches the ring to the blank, then it is easier to remove it and reinstall it.

As a result of such repairs, the rod retains its strength, flexibility, slightly changes the structure, but at the same time will allow you to avoid the purchase of an expensive exclusive knee. For the money spent, for any ordinary spinning player such repairs will cost a negligible amount

It is always necessary to take into account the feasibility of restoration using the method described above - for example, when telescopic spinning rods made of fiberglass or composite, which have less wall thickness, strength and flexibility, break, it is best to choose a new one to replace the damaged knee. The repair will not return the form to its original strength, it will make it significantly heavier, and if a serious predator bites, the repaired knee will break in the place of the previous damage.

Top repair

A broken tip is a very serious damage to the rod that affects its functionality.

When fishing with light jig baits for spinning rods, the tip is very important. Thanks to it, the angler makes long, accurate casts of miniature twisters and vibrotails. It allows you to make the game of baits more attractive. In addition, the tip is able to signal the weakest, hesitant bite before the angler feels it with his hand.

Repairing the tip of a spinning rod differs for a number of reasons from repairing similar damage to the butt or second knee. Its internal diameter is either very small (it is extremely difficult to select a suitable insert), or the tip is solid (does not have a cavity for a scupper repair connection). Any increase in the rigidity of the tip will lead to a change in its sensitivity, worsen the casting range, and negatively affect the performance of the bait. When loaded, the insert installed in the tip breaks the thin walls from the inside and completely disables this part of the rod.

Therefore, in order to eliminate this breakdown, you should resort to another more delicate repair method:

- We inspect the broken parts for longitudinal cracks;

- If no cracks are found, we process parts of the top in the places of breakage with a small needle file to a length of 15–20 mm from the edge. During processing, the varnish is removed and the thickness of the top wall is slightly reduced;

- We connect both parts with a spigot - a tube of thick paper, which we first lubricate with quick-drying epoxy glue. When connecting parts of the top, it is necessary to ensure that the throughput rings are located along the same axis;

- 20-25 mm below and above the joint we wrap sides of electrical tape, which will prevent glue drips from forming during further installation of the bandage;

- To eliminate breakage of the tip, carbon fiber is used. Since it is very difficult to buy it in a store, it is most often burned out from pieces of old high-modulus fishing rods. To burn out carbon fiber, take a piece of carbon fiber elbow 20-25 mm long and 10-12 mm in diameter. Holding the piece in pliers, hold it over the flame of a gas burner until the smoke stops coming out. Carefully unwind the tube with the burnt out binders, dividing it into a strip of carbon fiber and a carbon mesh (backing);

- Lubricate the junction of the two parts of the broken tip with slow-drying epoxy glue diluted in a ratio of 10:1 with hardener;

- We wrap the backing over the glue, pressing it tightly to the joint;

- We wrap carbon fabric onto the substrate. We coat each turn of carbon fabric with epoxy glue;

- We forcefully wrap a layer of tape over the bandage;

- After the glue has hardened, use a sharp knife to remove the tape and duct tape edges;

- We grind the bandage under running water with a file, and then with fine sandpaper;

- We cover the bandage with waterproof varnish.

With this method of repair, the place where the tip of the spinning rod broke is almost invisible, and the rod itself retains its strength, flexibility and other important properties.

Spinning rod repair

Repairing a fishing rod with your own hands is quite possible. The following elements are required as basic materials:

- a tube of the required diameter (this part should be approximately twice as long as the crack that has formed);

- Kevlar cord (it is possible to use a flat spinning cord);

- waterproof epoxy resin;

- in case of increased loads at the site of failure, you should stock up on glass or carbon fiber;

- scotch;

- film or other film.

Read more

Spinning rod “Norstream”

Repair of spinning rods begins with the preparation of materials. The tube must be sanded and lubricated with resin, after which it is ready to be installed in the elbow. The fishing device must be restored to the same condition as it was before the breakdown. The selected fabric material is cut out in the form of a rectangle and lubricated with adhesive, then it is wound around the crack site. The film strip along with the tape will help remove excess resin. To increase the strength of the structure, a purchased cord is wound around the fabric.

The repair of spinning rods begins with the preparation of materials.

After completing all the steps, it is recommended to place the tackle vertically and let the glue dry for 24 hours. Repairs to the spinning rod blank should be carried out in a timely manner. As soon as the smallest crack has formed, it urgently needs to be eliminated, otherwise the entire structure may break.

Handle repair

Among all the materials used to produce a spinning rod handle, one of the most common is cork. Having many advantages (softness, a pleasant-to-touch surface, the ability not to harden in cold weather), this material has one big drawback - with prolonged use, pits, cracks, and chips form on it, leading over time to the destruction of the handle.

For small cracks:

- Grind the cork from a wine bottle on a fine grater until it becomes fine chips;

- Mix the resulting shavings with PVA glue, fill all defects with the resulting composition;

- After the glue has dried, sand the surface with fine sandpaper;

Instead of this composition, you can use a wood putty that matches the color.

For large holes and cracks:

- We cut out the damaged piece by making a rectangular notch in the cork covering of the handle;

- From a cork that does not have internal cavities, cut out a piece (insert) slightly larger than the recess;

- Lubricate the recess and insert with waterproof PVA glue;

- We press the insert under force into the recess and fix it with electrical tape;

- After 12-14 hours, remove the electrical tape and cut off the part of the glued insert protruding above the surface of the handle with a sharp knife;

- Clean the handle with fine sandpaper.

The tip of the spinning rod broke: do-it-yourself repair of this and other rod breakdowns

Every angler has experienced a breakdown of his fishing rod at least once in his life. This happened under different circumstances. Naturally, the question arises of how to repair a spinning rod with your own hands: the tip is broken, the tulip needs to be replaced, the handle has deteriorated, or the reel seat has stopped working. What to do?

Too serious damage to the fishing rod leads to a complete loss of its performance. It is almost impossible to restore it. However, more often the defect turns out to be minor and must be eliminated. As a result, you can continue fishing with a repaired spinning rod.

You can have your fishing rod repaired by craftsmen who specialize in repairing fishing gear. The work of such professionals costs money, but the result is a spinning rod that has not lost its original characteristics and remains just as durable and reliable.

Very minor breakdowns can be fixed on your own, especially those that do not require the use of specialized devices, materials and tools. Everyone at school had labor lessons, so everyone can cope with minor damage.

Immediately after purchase, the angler handles the rod very carefully, even overly carefully. As a result, the spinning rod does not “open up” completely and it seems as if the purchase does not meet expectations. This behavior is typical for beginners, for whom this fishing rod is their first or second serious acquisition.

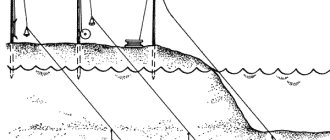

Over time, the angler gets used to the spinning rod, begins to behave more boldly and in some situations loses his vigilance. Such negligence most often leads to rod breakage. While on the shore, on the way to a reservoir, or when storing at home, the following troubles may occur:

- Inexperienced fishermen often break their spinning rods when fishing incorrectly. Moreover, the form can “form” not only from captured specimens. The most common mistake made by beginners is the desire to quickly pull the predator ashore, and he pulls it straight ahead or tries to throw it onto land with a fishing rod. Also, when trying to take the fish with your hand, the rod is pulled back excessively behind the head. As a result, an angle of less than 90 degrees is formed between the fishing line and the blank, which can lead to trouble if there is a sudden sudden jerk.

Defects that arise during the manufacturing process of the blank and assembling the rod occur much less frequently than due to the negligence of spinning players. If we compare breakdowns associated with manufacturing defects and improper handling by the fisherman, the score will be 1:9 in favor of the second factor.

To avoid spinning rod breakdowns, you must always be careful and focused. Basic rules for handling gear should be observed. Fishing rods should be transported for fishing folded in a hard case or in a tube.

Not all breakdowns can be fixed with your own hands. But still, some are “treated” quite successfully, and with some experience in such work, it is almost impossible to notice that the fishing rod has been repaired. The main defects that you can eliminate yourself are:

- rod tip breakage;

- replacing the tulip;

- replacing the ring;

- elimination of defects in cork handles.

Let's consider each case separately.

Of the defects listed above, this is the most complex. To repair the tip, you will need to select an internal rod of a suitable diameter. For example, for ultralight fishing rods, you can take a sewing needle. It has a decent margin of safety, and at the same time its elasticity will have almost no effect on the operating parameters of the spinning rod.

- Both ends of the broken form are cleaned and degreased.

- The rod is lubricated with epoxy glue and inserted into the form.

- Let the glue dry.

- For reliability, the joint can be coated with colorless varnish or a bandage applied to it.

That's it, the repair of the spinning rod is completed, you can go to the pond.

Photo 1. Instead of the broken red tip, a new blue one was glued in.

The need to replace the tulip may arise in the following situations:

- formation of chips and other defects on the insert;

- careless handling that led to a change in the shape of the tulip frame;

- breakage of a small section of the solid tip of the spinning rod.

In all cases, the fisherman needs to choose a suitable tulip. To do this, you should measure the diameter of the tip and select the desired product model from the catalog of manufacturers of spinning accessories.

- We remove the old tulip, having previously heated the place where it is attached with a lighter or candle.

Photo 2. The removed tulip and the cut off tip of the fishing rod.

- We clean the seat with fine sandpaper and degrease it with alcohol.

Photo 3. We clean the tip to the depth of the tulip.

- Then we apply epoxy glue to the tip.

- We put on the tulip, maintaining alignment with other access rings.

- We are waiting for the glue to harden.

That's it, the tulip has been replaced, the spinning rod looks like new.

The algorithm for replacing this element is similar to installing a new tulip:

- We purchase a new pass ring, choosing it according to the inner diameter of the insert.

- We remove the old one, heating the attachment point and removing the braid.

- We install a new ring, gluing it with epoxy glue and placing a bandage made of durable nylon thread on top.

- Let the glue dry. Cover the top area where the ring is installed with colorless varnish.

Photo 4. A ring wound with threads coated with black varnish.

During the installation of a new guide ring, we make sure that the alignment is not disturbed. This is fraught with a decrease in casting range and the need to carry out repairs again.

Over time, chips and other defects appear on the cork handle. This causes some discomfort when fishing and does not look aesthetically pleasing. This nuisance can be easily restored. To do this, you will need glue and cork material, which can be used as a regular champagne or wine cap:

- Grate the cork.

- Mix the resulting shavings with PVA glue.

- We cover the existing defects with this mixture.

- Let the glue dry.

- Clean the handle with fine sandpaper.

The result is a refurbished handle that looks like new.

Repair of access ring

Often the internal metal-ceramic liner in the passage ring fails. The process of repairing such an element is very simple:

- We buy a set of rings of different diameters with internal inserts of the same or better quality as on the rod;

- We select a passage ring with a suitable diameter;

- Using a sharp knife, carefully remove the inner metal-ceramic liner from its metal frame;

- We remove the damaged liner from the frame using pliers, clean its inner surface with a small needle file;

- We insert the new insert into the prepared frame of the access ring and fix it by gluing it on both sides at the junction with the frame with super glue.

In case of damage such as a crack in the support leg or wire frame, it is better to replace the ring with a new one.

Replacing rings

Replacing rings consists of the following simple manipulations:

- It is better to start replacing the lower large ring, gradually moving towards the top;

- In order to remove the ring, we heat the place where it is attached to the form over a lighter until the varnish covering the fastening winding made of thin nylon thread softens;

- Using a sharp knife, cut the winding layer parallel to the plane of the form;

- Remove the winding and ring;

- We clean the area from any remaining varnish, winding, and degrease;

- Apply a little epoxy glue;

- We install a new ring, fix it tightly, winding a nylon thread over it in even turns;

- Apply a layer of colorless waterproof varnish on top of the thread;

- In order to remove the last ring - the tulip - a thin wire is attached to it, heated over a candle flame, while at the same time trying to pull the ring off the top with the wire.

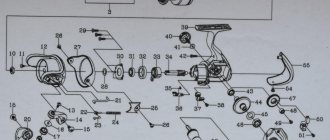

Spinning reel repair

Among the most common coil malfunctions and how to fix them yourself are:

- Noise inside. Disassemble the reel, remove sand and dirt from the drive mechanism, check the bearings in the handle and spool, and replace if necessary.

- Rotation mechanism jammed under load. Replace the drive gears with new ones;

- The line-laying arm snaps spontaneously when casting. Tighten the screws that secure the temple. If this does not resolve the problem, replace the spring responsible for latching the shackle with a stiffer one;

- The reverse stop does not work. It is necessary to lubricate the overrunning clutch, which is responsible for the operation of the mechanism;

- Creak. It is necessary to add lubricant inside the reel body;

- The fishing line gets under the front clutch nut and breaks. It is necessary to replace the thick felt gasket under the nut with a thinner plastic one.

These methods will allow you to effectively repair the reel with your own hands, eliminating serious problems, extending the life of this expensive component of spinning gear.

Read: Repair of spinning reels