Most malfunctions of spinning reels that arise during the operation of the latter can be eliminated independently. In other cases, you still have to contact a workshop, where experienced professionals will repair any reel for a fee.

With both options, the owner will be able to not only save significant money, but also continue to use the favorite model rather than buying a new one. Before reviewing common breakdowns, it would be useful to remind you once again that the efficiency and durability of any reel largely depends on regular maintenance!

When buying a new reel, pay attention to its manufacturer; you should give preference to reels from Shimano , Daiwa and Ryobi .

Frequent coil malfunctions:

- Coil creaking

- Noise inside the coil

- The reel mechanism jams under load

- Self-resetting line handle

- Reverse stop failure

- Damage to the spool edge

- Line breaks under the clutch nut

- Spiral line feed

- Uneven line winding

- Self-tightening of the clutch

If you want to understand the topic of choosing spinning reels in more detail, we recommend our interesting review - link.

Coil creaking

If constant squeaks occur inside the coil, it is necessary to lubricate its parts. Of course, it is not so easy to determine which parts require lubrication, so the best option in such a situation would be to completely lubricate the entire reel mechanism. If you have at least basic skills in disassembling, cleaning and lubricating the insides of the reel, no difficulties should arise. How to disassemble, clean and lubricate the coil, read the article - Coil Maintenance.

Scheduled reel maintenance

Before full maintenance, prepare everything you need in advance

In addition to being careful, the reel needs to be serviced once or twice a season. The concept of a fishing season is quite flexible - from a few short months in the north and all year round in the south of our country, so be guided by your “aviness” - with active fishing, maintenance will be needed in about 3-4 months.

The best solution would be to take the coil to a technician for service, but if you want to do the maintenance yourself, here is the procedure:

- Remove the spool and handle and set aside. Remove the adjusting washers, ratchet and bearing, if any, from the reel rod;

- Remove the rotor by unscrewing the rod nut and locking bolt;

- Now disassemble the reel body, removing the covers if there are any;

- Remove old grease with a cotton swab dipped in alcohol. Remove only from places where you can easily reach it - do not force this process and do not try to achieve absolute cleanliness;

- Apply thick lubricant to the main pair. Do not overdo it - the volume of lubricant should not be large, just a couple of peas will be enough;

- Lubricate all visible bearings and overrunning clutch with liquid lubricant;

- Loosen the screw of the line roller; there is no need to unscrew it entirely. Drop a drop of liquid lubricant under the bushing or bearing and disperse it by rotating the roller. Carefully tighten the screw all the way;

- Reassemble the coil in reverse order, tightening the bolts without force;

- Disperse all the lubricant by rotating the handle in different directions. If the rotation occurs smoothly, without biting or extraneous noise, then this means that you have done it!

If at the disassembly stage it turns out that the old lubricant has coked or hardened, this means that the bearings will have to be washed before adding a new portion. If you are not confident in your abilities, then it is better to take the coil to a service center for this procedure.

Uneven line winding

Sometimes a small incident arises, which consists in uneven winding of the fishing line, when a front or rear cone forms on the spool.

This minor error can be easily corrected as follows: winding the line with the cone down is eliminated by removing one washer from the main shaft of the reel, and the problem with the direction of the line cone up is eliminated, on the contrary, by adding another washer.

Self-resetting line handle

A fairly common problem is when the line laying arm automatically resets to the position for reeling in the fishing line, which can often lead to disastrous consequences. To fix this problem, you should first try to tighten the bolts that secure the bow. If this simple procedure does not help, you should add more elasticity to the spring under the cover. This can be done by installing a spacer on the rod or simply installing a new, stiffer spring.

Some common problems and their solutions

In the process of using fishing reels, depending on their design features, sometimes problems arise that can be quickly eliminated:

- Self-activation of the line laying device. During casting, its bow is thrown off, which can lead to breakage of the tackle, and sometimes to damage to the rod. Usually, to fix this problem, it is enough to tighten the bolts securing the arc. If this does not help, you need to change the inner spring to a more elastic one.

- Loss of handle. Oddly enough, this happens very often. To prevent this, always monitor its fastening and tighten the fastening washer in time.

- Uneven winding of the cord (fishing line) with a cone in one direction. This interferes with the correct operation of the gear and reduces its sensitivity. This is often associated with washers of different thicknesses located on the shaft. Accordingly, if during winding a cone is formed, directed downwards, then you need to remove one washer, and if the cone is directed upwards, then you can try adding one washer.

- When casting, the line comes off in a spiral. Most likely, the roller of the line-laying mechanism is very dirty, the bearing does not work as it should and practically stops rotating. To correct the situation, it is necessary to disassemble the mechanism, clean and lubricate all parts.

You also need to learn and always remember that if during the fishing process you hear any sounds from the reel body that are uncharacteristic for it, or feel vibration, you need to stop its operation . Most likely, severe contamination of the internal mechanism has occurred, which can lead to its breakdown. It needs to be disassembled, cleaned and, depending on the problem identified, either replace the parts or simply lubricate them. But this must be done in prepared conditions.

Noise inside the coil

If you hear unnatural sounds coming from the coil, it is advisable to stop using the product immediately. The appearance of noise may be associated with the same contamination, as well as with the breakdown of bearings or other parts. Further actions are to disassemble the coil and then lubricate or replace damaged parts, depending on the specific problem.

Benefits and procedure for preventative coil maintenance

The more often a coil is used, the more it is exposed to unwanted stress and wear. When going fishing, during operation, its mechanism is affected by the following factors:

- Various blows to the body and handle. This usually happens when transporting gear, when actively playing fish, etc.

- Forceful impact when catching or when fishing for a trophy. In such cases, its mechanism is often affected by forces that exceed its design capacity.

- Contamination of the reel mechanism elements. In the process of fishing, very often it ends up in water in which there is a suspension of sand and mud, and in addition, equipped fishing rods, intentionally or forcedly, are placed on the ground, in the grass, on the sand. It is especially undesirable for dust, sand or dirt to get on various rubbing and rotating parts, for example, gears, in which case these contaminants act as an abrasive material that can damage them.

Timely maintenance of spinning reels helps to minimize the possible negative consequences of these and other factors. In addition, it is important to consider its purpose and what load it is designed for. For example, 1000 or 1500 reels cannot be placed on a trolling rod; they will most likely break on the very first fishing trip.

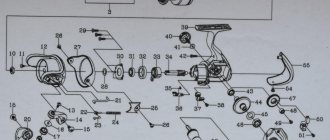

The periodic maintenance process for coils consists of the following steps:

- Preliminary external cleaning of the product from dust and dirt.

- Disassembling the coil to gain access to the elements of the mechanism.

- Cleaning and lubrication of the component elements of the mechanism.

- Product assembly.

- Functionality check.

Depending on the model, the assembly and disassembly of coils may differ in some nuances, but in general this process for all inertia-free coils follows the same algorithm .

The reel mechanism jams under load

When, when reeling in the fishing line, knocking noises inside the reel are clearly audible, it periodically jams and even jams under some load, we can safely say that the main gear mechanism is damaged. Most likely you will need to replace the drive and driven gears with new ones.

Types of spinning rods and reels

There are two main types of spinning rods:

- Telescopic. One that folds up like a spyglass or telescope. Its rod is evenly divided into knees, the structure is empty inside. Which allows it to fold (the thin part into a slightly thicker part).

- Plug (knee). The knees in the rod, between each other, are tightly secured with tubes. Such spinning rods are more convenient and reliable to use.

Read How to deliciously salt sockeye salmon

A broken spinning rod with a telescopic rod is easier to repair.

Types of spinning reels:

- Inertial coils of the “Nevskaya” type. This is the simplest type of reel. Often it does not even have a mechanism for braking the fishing line. The fisherman has to slow down the drum with the fishing line with his finger.

- Professional fishermen prefer to use a spinning reel. In such a reel, when casting bait, the spool (the place where the fishing line is wound) remains motionless. Only the fishing line unwinds. The main condition for using a spool is that it must be completely filled with fishing line.

- The latest development of specialists is an inertial multiplier reel. It combines the operating mechanisms of an inertial and inertialess coil.

The first two can be repaired yourself. Multipliers are very complex, and their repair is best left to specialists. The only problem with this reel that you can fix yourself is tangling of the fishing line.

Types of spinning rod breakdowns

The spinning rod breaks for two reasons:

- Manufacturing defects. This reason for further damage can be detected upon purchase. The main thing is to choose carefully;

- Breakage occurs due to the fault of the fisherman. Due to inept handling of gear and improper transportation. More than 90% of breakdowns occur for this reason.

Let's look at what types of rod breakdowns can occur.

- The rod (knee) breaks in half.

- Breakage of the tulip, the very tip of the spinning rod. Often it breaks off at the base.

- Top breakage. Often breaks in the middle or beginning of the last section.

Types of coil damage:

A gap has formed between the line laying roller and the lever. The line gets stuck there, and this causes a lot of inconvenience.

- Failure of the line guide return spring.

- The reel rotates slowly and jams.

- Bow transformation.

- Loss of gearbox cap.

Damage to the reel spool

The presence of damage on the side can significantly affect the casting distance, and, naturally, only in a negative way. Also, due to scratches and unevenness of the spool, the fishing line itself often suffers, and its service life is reduced.

Therefore, after detecting such defects, hurry to eliminate them by grinding and polishing the surfaces. In some modern reels, a special coating of a hard metal alloy is applied to the side of the spool, which it is advisable to leave in place.

Important article on this topic: the best spinning reels

Coil characteristics

When purchasing, you should pay attention to the following technical characteristics of a spinning reel:

- spool size;

- rotor rotation speed;

- weight.

The spinning reel is designed as follows:

- handle;

- anti-reverse;

- spool;

- friction clutch (brake);

- line layer (line holder).

Rotor speed and mechanism

The reel is equipped with a rotor. Its rotation mechanism consists of 2 elements:

- Bobbin feed devices.

- The main pair (transmits rotation from the handle to the rotor).

The rotor contains the following parts:

- Driven gear.

- Drive wheel.

The wheel shaft has a 4-sided hole for the reel handle. When the handle rotates, the drive wheel also rotates. As a result, the driven gear rotates the rotor.

The main pair is a gearbox with a gear ratio (for example, 4.6:1, 6.5:1, etc.). The ratio of the first and second numbers is the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear.

Inertia-free reel mechanisms

The more powerful the rotor, the larger the diameter of the gear in the gearbox (main pair).

The bobbin feeder is a carriage and other elements that periodically return to their original position. There are 2 types of device:

- Crank gear.

- Screw feed (reduces backlash).

Read Fishing in Vladivostok

The device with a crank link has the following parts:

- small gear (on the wheel shaft);

- parasitic gear;

- carriage + guides;

- stock.

The rotation from the handle is first transmitted to the small gear, and then to the “parasite”. As a result, the gear moves the carriage.

Handle

The handle rotates the spinning reel mechanism. However, sometimes you have to move it to a comfortable position (under your right or left hand).

Spinning reel handle

To rearrange the handle, you must perform the following steps:

- Remove the nut on the clutch and spool (or press the release button).

- Remove the washers. Moreover, you also need to remove the gears located under the spool.

- Unscrew the handle.

- Reposition the handle. Moreover, the handle must be moved to the opposite side of the reel body.

- Screw the screw into the hole.

- Place the washers and gears located under the spool.

- Place the nut on the clutch and spool (or reinstall the lock with the button).

High-speed fishing reels are equipped with a double handle. They also have one handle with a compensator. The compensating device prevents vibration caused by unbalanced spinning reel handles.

Anti-reverse

The reverse stroke of the reel on a spinning rod means the rotation of the handle and rotor, which is directed towards winding the line onto the spool. The overrunning clutch is responsible for blocking the movement of the handle towards itself. Thus, during fishing, anti-reverse does not allow the rotor to turn in the opposite direction, and the line does not “get stuck” and form unnecessary knots.

Anti-reverse is installed inside the coil. A lever is installed outside its body to disable the reverse rotation stopper or activate it.

Modern reels are equipped with instant anti-reverse. It is also ideal when using low-stretch braided scaffolding.

Friction clutch

The drag adjusts the tension force required to pull the line from the spool. As a result, it reduces the impact force and reduces jerks both when playing and when hooking.

The friction clutch also protects the rod from heavy loads. This prevents the fishing rod from breaking and the line from breaking.

Spinning reel clutch

When adjusting the clutch, the braking force must be adjusted so that it is 1/3 less than the tension force of the fishing line used. Thus, for fishing, fishing lines are used with a breaking load of 6.0 kg. As a result, the clutch should produce such a force that a fishing line of 4.0 kg is released (released).

As a result, the life of the fishing rod is extended. After all, after adjusting the friction, the fishing rod is subjected to less load.

To successfully adjust the clutch, you need to bring the fishing tackle into working condition. The algorithm of actions looks like this:

- A bait hook is placed on the line.

- The fishing line clings to the tree.

- When moving away from the tree, the position is taken as when playing.

- The fishing rod is bent, and the line is stretched as much as possible.

- The clutch is released to the ratchet.

The clutch adjustment has been successfully completed.

Spool dimensions

Another important parameter of a spinning reel is the size of the spool. Each figure of a fishing rod is the product of the length of the line and its diameter. This determines the capacity of the spool.

For catching small fish, spools up to 2500 are suitable (with a weight of up to 5-20, 7-21 and 5-25 g). For medium-sized fish, products from 2500 to 3500 (max) are used. For catching large fish, spools of 4000 and above are used.

Line breaks under the clutch nut

In reels with a front drag, the locking nut is located slightly above the edge of the spool, only about 1-2 mm. Because of this, the line often gets caught on the nut and gets under the edge, which leads to tangling and breaks. To eliminate this problem, you need to disassemble the coil, remove the nut and washers of the friction brake, and replace the felt spacer with a thin plastic spacer.

Reel repair by a specialist

In difficult situations, in order to repair your favorite coil model, it is better to seek help from a specialist who already has dozens of repaired and correctly configured coils behind him. Masters who repair spinning reels have at their disposal a wide range of parts for products of any category, and therefore they will probably have something to replace the damaged element of your model. An experienced specialist can carry out not only the repair itself, but also lubricate the parts along the way and make precise adjustments of the main pair of gears.

Coil lubrication

Another reason for coil breakdowns is the lack of lubrication of the internal mechanisms. After each cleaning of sand and dirt, the parts must be lubricated. The oil used for this purpose should not be too thick, without various additives that can damage plastic parts. Naturally, it is better to buy special oil designed specifically for lubricating coils.

Careful operation and periodic maintenance will extend the life of the reel and protect it from damage. If the latter do arise, you need to promptly take care of repairs at an early stage, so that a minor problem does not turn into a large or even critical one.

Author of the article: Vitaly Leonidovich Ivanov, 2021.

Carp life hack. Equipment repair and maintenance

In all areas of human life, there are small tricks that are brilliantly simple, but make life much easier. Today we will tell you about some secrets that will be useful to all carp anglers without exception. Carp life hack!

Carp life hack No. 1. Repairing a tent or shelter

Anything can happen when fishing and sometimes the fabric of our shelters is subject to various mechanical damages. We won’t describe now how this can happen, just let’s take a situation - you have a hole in the roof of your tent, or shelter.

Today, in the clothing industry, the same leather products are successfully used, so-called patches. They can be in the form of a figurine, or just a piece of fabric. Sold in a variety of colors and sizes. They are called “clothing repair patches.” The leading manufacturer in 21st century patch manufacturing is McNett. Which offers you two types of patches - from CORDURA and Tenacious Tape. Despite the fact that we remember Cordura from the eternal bags of the FOX FX series, Tenacious Tape material is best suited for tents. It belongs to the Gear Aid line and is intended specifically for repairing punctures, cuts, tears, etc.

They can be used to repair inflatable products, backpacks, bags, and the repairs can be performed on the go, which is very important!

Sample patch from McNett

Just cut off the piece we need to size

Glue to the slot

All is ready!

It’s hard to believe, but everything is really as simple as in the photo and does not require any complex operations or the use of various glues and presses.

Carp life hack No. 2. Improving lightning performance

To prevent the zippers of your shelter, tent, or sleeping bag (which is especially important), use the old proven method that our grandparents used. Take a piece of candle wax and rub it on your zippers. Even if you just bought the item and it is very, very new, it will be impossible not to notice that the zippers open and fasten a little faster than before they were waxed.

Carp life hack No. 3. Prevention of rod joints

Don't move the candle too far! Now is the time to pay attention to the knee joints of your rods. We hope that you follow the rules for caring for your rods, but we still recommend that you also wax the joints of your rods.

This will add smoothness, increase glide, and extend the life of your blanks. Please note that this does not in any way affect the fact that when casting the joint will begin to slip out of the lower knee. Only on the condition that you do not check the joints before casting, and this must be done even under normal conditions when you do not use wax.

Read: Catching chub with a spinning rod

Carp life hack No. 4. Cleaning the coils

WD-40 aerosol was invented in 1953 in California. The creator's name is Norman Larsen. Initially, this liquid was intended as a water-repellent agent that would resist corrosion. And only a couple of years later it turned out that it also has many options for household use. Half of the composition is white spirit solvent, a quarter carbon dioxide, 15% mineral oil and 10% inert ingredients. By the way, sea fishermen love to use it, lubricating their fishing gear with it. There is even a legend that WD-40 contains fish oil, since it was noticed that larger fish were biting on gear treated with this spray.

We do not suggest you use WD-40 as a dip, but cleaning the coils and lubricating their mechanisms is more than enough! Please note that you need to use WD-40 with the addition of SILICONE!

Carp life hack No. 5. Prevention of telescopic stands

In the same way, you can carry out preventative maintenance on your telescopic stands, which will extend like clockwork!

Full or partial copying without the consent of the portal editors is prohibited