An inflatable PVC boat is a practical and affordable watercraft, which is preferred by many modern fishermen. This popularity is due to the fact that this boat, unlike a plastic or metal one, does not take up much storage space and is easy to transport. The inflatable boat easily folds to a compact size and is convenient to transport. But how to fold a PVC boat into a bag correctly? We will tell you briefly and with examples.

General tips for folding PVC boats

- It is more convenient to fold the boat on a flat surface. Find a suitable location outside in the summer or in a heated garage in the winter.

- The boat needs to be laid out, cleaned and dried, after removing the components.

- Once it is dry both outside and inside, you can check it for defects and pump out the air if there is no need for repairs. Use a pump for this or simply gently press the folding parts with your knee. Air will gradually escape from the open valves.

- Before rolling up the boat, it is recommended to sprinkle it with talcum powder to absorb moisture and protect the material from dampness.

- When folding, the already folded part should not warp relative to the part that has not yet been folded. Otherwise, it will simply be inconvenient to put the boat into the bag.

How to disassemble an inflatable boat: valuable tips

In order for the boat to last as long as possible and be easy to transport, it must be disassembled only after thorough cleaning and drying, both outside and inside. Before deflating the cylinders, all components and rigid elements should be removed and checked for defects. If there is no need for repairs and the entire surface is intact, then you can pump out the air using a pump, while lightly pressing the folding compartments with your knee. This will ensure gradual air release from the cylinders and eliminate the risk of damage to the seams from excessive pressure.

To protect PVC from exposure to dampness and completely absorb moisture, the boat is treated with talc before rolling. During the rolling process, the fully deflated parts are folded in half along the length of the boat to create a width less than the length of the storage bag. Roll the material into a roll so that you get a bundle without protruding elements and having the correct shape. Finally, use a sling to secure the package and place it in the bag.

How to fold a boat with floorboards?

Floorboards are removable panels that form the flooring on the bottom of the boat for added rigidity and reliability. The folding instructions are quite simple:

- choose a flat place and unfold the boat;

- remove air from the cylinders;

- remove the payols;

- if there is any remaining air, pump it out using a pump;

- Carefully fold the parts of the vessel first along the keel, then roll them up and secure them with a fixing tie.

Assembling a boat - rules and sequence

As a rule, our air frigate is stored in a special bag.

They are usually sold with Velcro fasteners on the sides, so they provide a canvas on which to disassemble the boat. In the bag it lies deflated, rolled into a roll - this way it takes up less space and the possibility of damaging the rubber is minimized (only if you do not pierce it right through from above). It is better to unroll the boat from a roll on a clean plane. It must be free of sharp objects that can quickly damage the upholstery of the vessel. It is convenient to use a bag as a lining. Having spread it, you next need to turn the boat to its full length, and then, a little, less than half the required air, inflate it. After this, floors are installed on the bottom - strong plates that allow the “floor” of the boat to remain hard so that you can move on it not like on a trampoline. Installation order: bow, second, third, stern, fourth and fifth at an angle so that the deck is level from edge to edge. The bow and second floors are connected with aluminum fasteners; it is also advisable to fasten the remaining ones, this will prevent slipping.

Next is the stringer. Stringers are longitudinal ribs that give the boat rigidity to resist water; they look like metal sticks, shaped like a baseboard. To make it easier to install the ribs, we recommend placing oars under the boat where the stringers should be - this will lift the vessel a little. They need to be installed symmetrically, on top of the floors.

All! The difficulties are over, all that remains is to pump up the PVC boat. We fill the cylinders with air and install the seats. We inflate the remaining parts in the following order:

- aft;

- nasal compartment;

- keel (middle of the bottom);

- all remaining parts to the maximum.

Be sure to plug the valves into the holes and insert the oars into the sides. After this, the boat can be launched and used - it is fully inflated and ready for sailing. Don’t forget to check whether everything was done correctly: on the water, as in the air, a lot of different incidents can happen solely due to inattention.

How to fold a boat with a transom?

The transom is the structure on which the motor is fixed. It is located at the back of the boat. To fold this model of watercraft, it is better to ask a friend for help. An extra pair of hands will definitely come in handy. The procedure is as follows:

- it is necessary to release some of the air from the sides and keel, if any;

- at the same time we remove the floor profiles;

- We connect the pump to pump out the rest of the air and begin to roll up the cylinders from the transom side. Direction: in half and lengthwise;

- you need to tuck the inflatable sides under the transom and, in a half-bent form, set them in the direction of the bow so that there is no distortion. Now you can roll it up;

- It is advisable to roll the bow of the boat inward rather than leave it wound on the outside.

If you get a neatly shaped package with no protruding elements, then everything was done correctly. All that remains is to secure the folded boat with a sling and place it in the bag-cover. It will be more convenient to pull it from above and roll the boat from place to place. For floor profiles, a different cover is usually provided; they are stored separately.

Let's sum it up

So, to fold a PVC boat according to all the rules, you need to:

- Learn how to properly fold a PVC boat;

- Prepare the vessel by cleaning and removing accessories and boat fittings;

- Arm yourself with a pump;

- Disassemble the payol according to the rules;

- Bleed the air from the boat compartments;

- Carefully fold the sides lengthwise;

- Start assembly from the stern;

- For a boat with a transom, use it as a wrapping press;

- Don't forget to prepare your packing bag;

- Protect from rodents during storage.

How to fold a NDND boat with a keel

We are talking about a PVC boat with a low-pressure inflatable bottom. That is, instead of a hard floor there are inflatable sections (one or several). This can be called both the main advantage and disadvantage of the craft. On the one hand, the boat becomes lighter in weight and easier to transport, on the other hand, you need a high-quality pump, since you will have to quickly pump out the air from all these sections. Otherwise, the procedure will differ minimally from the instructions for folding a boat with a hard bottom. You will find it in the text above.

Step-by-step instruction

Before folding the rubber boat, you need to remove the accessories and fittings from it. After this, the product must be thoroughly washed with a soft sponge with soapy water, dried well, and the air pumped out so that the cylinders are not completely deflated. They are folded like an accordion and pressed to the bottom. If the boat has a stationary transom, the cone-shaped ends of the cylinders are applied to it. The boat is then carefully rolled from the transom to the bow, squeezing out the remaining air. The result should be a cylinder without sharp corners or folds. They put a bag on top of it, turn it over and fasten it.

The rules for assembling rubber models with a hard bottom and pads have nuances. They, too, must first remove the components, oars, rowlocks, then thoroughly wash, dry, and lower the inflatable compartments. The slan-book is carefully folded, starting from the stern. On the floorboards, they disassemble the stringers, find a recess in the aft part, grab it and slowly pull the flooring towards themselves. If it is prefabricated, such manipulations are carried out with each part. The payol is placed in the bag intended for it. The air is pumped out of the boat, the sides are pressed to the center of the bottom, the ends of the cylinders are pressed to the transom, twisted and packed in a bag.

How to fold a PVC boat correctly: video instructions

Despite some differences in the design of the boats, the principle of operation when folding them is similar. But, as they say, it is better to see once than to read a hundred times. Therefore, we invite you to watch the video instructions to better understand all the points described above:

An inflatable PVC boat is a comfortable watercraft with a whole list of advantages. In order for it to serve you as long as it should, it is important to take good care of it. Clean thoroughly after each use and dry, do not leave in direct sunlight. And, of course, fold and store it correctly. Not only the convenience of storing the assembled boat, but also its safety depends on this.

Question answer

Question: What is the best way to pack a PVC boat into a bag?

Name: Matvey

Answer: This must be done on a flat surface. First, the boat is unfolded, cleaned, and dried. The components must be removed before doing this. The boat is deflated, sprinkled with talcum powder and rolled up so that the folded part does not warp relative to the part that has not yet been folded.

Question: How to properly and safely fold a PVC boat with a transom?

Name: Ivan

Answer: First you need to release some of the air. The remaining air is released by the pump, and at the same time the cylinders are rolled up from the transom side in the direction: in half and lengthwise. Next, the sides are tucked under the transom. In a half-bent form, they are given the direction towards the nose to avoid distortion. Now comes the folding process: it is better to fold the nose inward.

Question: How can I roll up a PVC inflatable boat with payols?

Name: Matvey

Answer: The boat is unfolded, air is removed from the cylinders, and the floor covers are removed. Next, the remaining air is expelled and parts of the boat are carefully rolled up, first along the keel, then rolled up and fixed.

Question: How to correctly and quickly fold a PVC boat with NDND?

Name: Vladimir

Answer: The procedure is usual, but you will need a powerful pump to quickly pump out the air from all sections.

Share link:

How to properly fold a PVC inflatable boat: Instructions (Video and Photo)

An inflatable boat is not only an affordable, but also a practical means of transportation on water. Unlike boats made of other materials, an inflatable rubber or PVC watercraft can be transported compactly. When folded, it is conveniently packed and stored in a specially designed bag. But in order to unpack the boat and quickly get it into working order, you need to fold it well and assemble it according to the rules. The Serious Fishermen's Club will tell you how to properly fold an inflatable PVC rowing boat or under a motor.

How to assemble a PVC boat with a hard bottom?

Boat floors (payol or slan) can be rigid or inflatable. Rigid ones, in turn, consist of several prefabricated elements. Most manufacturers recommend starting assembling the bottom from the bow and finishing at the stern, with the last section tucked under the clamps located on the transom.

Boats equipped with an airdeck (a low-pressure insert that replaces a floorboard) are inflated until the balloon has the desired shape, but is soft to the touch. Then the airdeck is straightened, or a floor is inserted, and the pressure in the cylinders is adjusted to the recommended values. At the next stage, the airdeck is inflated to 0.8 atm, and lastly the keelson.

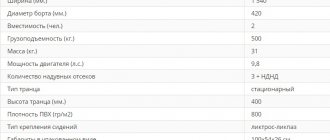

Some PVC boats, for example Taiga 340, are recommended to be inflated only with manufacturer’s pumps, so as not to overinflate and damage the integrity of the seams and transom fastenings.

Aqua motor rowing boats are assembled in a similar way. First, the cylinders are inflated to a semi-soft state, then the payol is collected. If its parts are numbered, starting from the bow 1,2,3,4, then first the 4th part is inserted under the block on the transom, then the 3rd, the next stage is the connection of the 1st and 2nd, then the 2nd and 3rd. The result is a house that needs to be sunk by pressing, and everything will fall into place. The final stage is the installation of stingers; they are, as it were, slipped under the assembled floor.