A boat has been an integral and necessary “tool of production” for a fisherman since time immemorial. And even now, when fishing has turned from a way of survival into a hobby, the question of choosing a boat for many fishermen (and even hunters) is more than relevant. A watercraft is necessary not only for fishing from the middle of the river. Often it is very necessary, just to get to the fishing point. Especially if the bank is overgrown with sedge or cattails, flooded, or access to it is difficult for some other reason. In these conditions, a boat for shallow water is especially relevant. It is also very important to choose the right motor for shallow water.

Reasons for the relevance of the choice

A body of water (river, pond, lake) where the depth is up to one and a half meters can be considered shallow. At the same time, very often its bottom is covered with a thick layer of silt, debris, driftwood, remains of building materials from collapsed or unfinished bridges, dams, etc. rest there. Most small rivers and estuaries are shallow water bodies to one degree or another.

To navigate them calmly, you need to have an optimal boat for shallow waters. A large vessel, such as a boat, is not always suitable for this. It can simply run aground, damage the propeller or engine shaft, or in the worst case, get a hole in the bottom. Boats for shallow water, including, for example, mountain rivers - fast, rough, but shallow, must have the following characteristics: • shallow draft; • small size and weight; • flat bottom or weakly expressed v-shaped keel; • durable hull + unsinkability reserve; • good stability; • special motor for shallow water. As a rule, either inflatable boats made of PVC or plastic ones have such characteristics - with a rigid hull made of polyester resins and/or composite materials. Outboard motors for shallow water are also subject to similar requirements - they must provide confident movement in a shallow area at low speed, while essentially working in the subsurface layer. At the same time, it is desirable for such a motor to have protection against silt, dirt, duckweed, etc., which are always abundant in small, often swampy rivers and ponds, getting into the mechanism.

Types of PVC tunnel boats

Tunnel modifications are motor and motor-rowing. In the first case, the boats are equipped with built-in transoms for motors with power up to 30 horsepower. The motor-rowing version is equipped with suspended transoms for low-power engines.

Boats differ in the type of bottom, which can be flat, inflatable or rigid, made of aluminum, plywood, or composite materials. The lightest models are those with a flat bottom. But they are inconvenient for use in the cold season. Thin floors do not retain heat well. Boats with inflatable and hard floors do not have these disadvantages.

Tunnel models are available for fishing, pleasure, and rafting. Each option is equipped with accessories that promote maximum operating comfort. Boats are divided by carrying capacity, number of seats, weight, and speed characteristics.

Choosing between PVC and plastic

An inflatable boat has been considered a fisherman’s “best friend” for many years. Its undoubted advantages are: • transportability; • small draft in water (even with a large load) • excellent stability. Inflatable boats are so stable that they can even withstand the accumulation of cargo and passengers on one side, whereas, for example, a boat can easily capsize. Due to their low weight, they can easily be dragged along the shore if the need arises. There is a wide variety of inflatable boats and boats for different purposes (including rescue operations at sea), but we are now only interested in a small watercraft for two or three people, rowing or having a quiet, low-power motor (up to 4 hp). The use of more powerful engines in this case is irrational. Since a shallow river, pond or lake, when moving along them, creates a danger of damage to the craft, the combination of a shallow draft with a flat bottom of increased strength is at the forefront. Attention! Steel and duralumin boats have the maximum strength, but they are designed for movement in deep areas. Wooden punts are not bad, but they have not been produced industrially for a long time. Therefore, when choosing an inflatable boat for moving in shallow water, you should opt for a watercraft made of PVC. This is polyvinyl chloride, used in combination with reinforcement with a special cord. In fact, the boat is made of a composite - a reinforced cord for rigidity, covered on top with multi-layered - from three to five layers - polyvinyl chloride material. Preference should be given to a five-layer PVC composite with a rigid cord, since there is a high probability of damage to the watercraft by any underwater object - from a stone to a snag. PVC boats have the following advantages over rubber ones: • High abrasion resistance. • High resistance to cord peeling. • High chemical resistance. • Relative ease of repair. The disadvantage of PVC boats is their weakness to sunlight. This material does not like being exposed to light for long periods of time, so the boat must be deflated or covered with an awning during storage. Rigid plastic or composite shallow-draft punt boats are also a good option for shallow bottoms. They are made from polyester (close to epoxy) resins by molding. They have a rigid frame. For shallow water, you can choose a plastic boat up to 4 meters long, with a side height of no more than 50 cm. Its advantages will be as follows: 1. Acceptable weight for dragging over a short distance. 2. Resistance to corrosion, sunlight, and other aggressive factors. 3. Relative strength. 4. Positive buoyancy in case of capsizing (although this is not relevant for shallow water). 5. Better handling compared to inflatable ones. The rigid polymer hull can withstand grounding or impact with a reef at low speeds, such as when paddling. Plastic cannot be torn, for example, during transportation by an accidental snag on a sharp object. But to transport even a small plastic boat to the fishing spot, you will need a car.

The main disadvantage of plastic boats is the difficulty of repair. A hole in metal can be welded, a hole in PVC can be patched using vulcanization, but it is almost impossible to repair a hole or crack in plastic at home.

A vessel that does not require modifications

Our team decided to create a boat that a person will buy, install a motor, and will not think about additional expenses , but will simply operate and enjoy their vacation.

It was decided to create a fiberglass bottom. Which already makes the bottom more protected compared to an inflatable one. And most importantly, it is possible to design the geometry of the tunnel for the correct operation of the water cannon, because it will be rigid and will not change shape during operation. However, fiberglass is not a panacea, because when passing over stones and driftwood, the bottom will wear out and become unusable. Using polycarbonate as bottom protection would be an interesting solution, because... it has high impact strength. But the team faced a problem; we did not have the technology to connect fiberglass and polycarbonate. After carrying out a number of experimental works, we were able to achieve the desired adhesion. We are now patenting this technology because the result is impressive. For additional protection, the lower part of the cylinder up to the seal was covered with polyurethane.

An important feature in the design of our RIB is that the insertion extends from the bottom by 3–4 cm , due to which the likelihood of damage is greatly reduced.

Just look at what our new vessel can do and everything will become clear without further ado:

In this video we conquer the Peschanaya River in the Altai Territory, demonstrating how passable our new development is. Our invention can overcome the smallest places in rivers where water barely flows. Jumping over boulders, driving onto pebbles at full speed and not being afraid of the consequences on the RIB JET 4500 MASTER is easy!

Motor selection

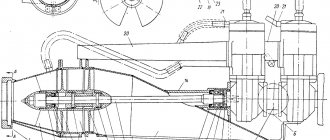

Unfortunately, highly specialized shallow water boat engines are rare. These include only aero propellers, which in principle are not immersed in water, but their use on domestic rivers and estuaries will look at least strange. Therefore, in principle, almost any engine can be used as long as it has the following qualities: • suitable for installation on your boat; • has adequate power; • has at least one, and preferably two or three, shallow water positions; • protected from drawing in silt, duckweed and dirt. In some cases, for example in clear water, it is possible to use water-jet propulsors that operate just in the subsurface layer. But they are completely unsuitable for swamp boats. Attention! A lot depends on the body of water where you are going to fish. Adequate power means a motor that is not very noisy and allows you to sail at a speed of about 4 km/h. The required power is in the range of 2-4 hp. Swimming faster is dangerous - you can damage the boat. The shallow position is a special fixation of the shaft and screw in the subsurface layer, the middle position between lowered and raised. It is best if the motor has several shallow-water “operation levels” - you can choose the most suitable one.

Also, pay attention to the material of the screw.

The screw must be made of steel, since aluminum or duralumin is easily damaged by the bottom. A good option is a carbon fiber propeller. With a low-power motor, choose a propeller with a large number of blades - 5, not 3. It will create more force. Since low noise is key for anglers, a battery-powered electric motor can be used. It doesn't have much power, but it works very quietly. Source

Building a boat

Of course, the first thing we do is consider material options and here we will immediately make our choice in favor of plywood. We will not list the advantages of plywood sheets, we will simply say that we will need FSF sheets of various thicknesses. This is a moisture-resistant material that we will treat with various means during the work process.

Model selection

Here we can’t help much, every lover of walking on the water has his own preferences, however, we will give simple parameters of the watercraft that we will have:

- The length of our structure will be 3500 mm, let’s convert it into meters for a better guide – 3.5 meters.

- 1350 mm – width, or 1.35 meters, which is quite suitable for a boat.

- Side height – 50 centimeters.

This is the option we will focus on for now.

Boat example

Important! The considered option is just one of many types of floating craft and does not mean an exact design exactly according to its patterns. The choice of boat type is made according to a large number of parameters.

Material purchase

Regardless of the type of boat, its structure and the number of seats, we will need basic materials, in which plywood for the boat will come first.

So, in order:

- FSF plywood 4 mm thick. We choose sheet dimensions of 1240x2450 mm for the agreed dimensions of the structure, and we will need three such sheets.

- Epoxy resin minimum 5 kilograms.

- One kilogram of hardener of your choice.

- Two to three liters of microsphere is a filler for epoxy resin.

Important! To make the work easier, the instructions for using epoxy resin may suggest using syringes rather than scales to determine the required amount of material. This is more convenient, especially taking into account independent work.

Cutting

There is nothing complicated in the cutting process; we make all the markings on the plywood sheet and start cutting the material. By the way, for cutting we will need a jigsaw.

Advantages of Scarab boats

The shallow draft allows the boat to be used at the shallowest depths and to approach the shore even in hard-to-reach places. This is a serious advantage for traveling along the rivers and lakes of Russia. In addition, you can equip your sports boat with additional equipment for wakeboarding and wakesurfing and get a lot of pleasure from gliding comfortably and safely through the water. ID series boats already have such equipment.

One of the main advantages that the Scarab has is a reliable Rotax jet engine with power from 150 to 250 hp. This is a maneuverable and high-speed boat - the speed can be maintained automatically thanks to the presence of several control modes.