Modern fishing is inextricably linked with the presence of a boat. It not only simplifies the fishing process, but also makes it effective. But it’s not enough to have a boat, you still need to move it to the fishing spot, which may be located at a considerable distance from home. In stores you can find special transom wheels that simplify the transportation process. It should be noted that there are various, very expensive products.

Content:

- 1 Functions of transom wheels

- 2 Advantages and disadvantages of having transom wheels

- 3 Types of transom wheels 3.1 Transformer KT-5

- 3.2 Automatic KT-3N and KT-3NU

- 3.3 Folding transom wheels

- 3.4 Tilting chassis, for PVC boats

- 4.1 Drawing

But, in order not to pay extra money, you can make such wheels yourself, at home, especially since there are no particular difficulties. They are especially necessary in conditions where fishing is carried out alone, although, as a rule, fishermen go fishing in groups of several people.

Transom wheels for a PVC boat are a transport chassis that is secured using 2 brackets. With the help of these brackets, the wheels are moved to the transport position or vice versa.

The presence of transom wheels makes the boat more functional. Without outside help, it can be moved along the shore, pulled out of the water and launched into the water. Their advantage is that there is no need to remove them when launching: it is enough to move them to the appropriate position.

In the process of equipping a boat with such a device, special attention should be paid to the placement of fasteners on the transom. Their position can affect the maneuverability of the boat, both on water and on land.

A little about transom wheels

First, let's remember what transom wheels are:

- Semi-automatic reversible. There is a spring-loaded reversible mechanism, due to which the disks or wheels take the desired position. When moving through water, they are located on the sides of the engine. Removed by unscrewing the nut. The problem is that in the raised position the wheels can become a nuisance, especially if a fish finder is attached to the transom.

2. On stiletto heels for NDND. The structure is attached to the transom surface with two studs. They are placed in the holes, wheels are put on them and secured with cotter pins. The difference between the first type is that more needs to be done for the wheels to take the upper position.

3. Quick release wheels. They do not rise, that is, with their help you can only move the ship on land. But after that it’s not difficult to disconnect them.

4. On clamps. They replace brackets. The system is removable and can be installed and removed very quickly. There is no need to make holes to install such wheels. But this option is not suitable for boats with NDND, because the lower transom area is not rigid and does not extend beyond the boundaries of the boat, that is, it will not be possible to install wheels.

There are also several types of chassis: inflatable, polyurethane and plastic. The first type is suitable for pebble shores.

Now is the time to consider the rules for the location of transom wheels.

All wheels must have two positions: for transportation and for swimming. The dimensions of the wheels and their racks do not exceed the dimensions of the transom and do not affect movement in any way or create any resistance in the water. It only takes a few minutes to install the transport wheels. After bringing the wheels into the desired position, the motor is installed in its place, the boat is lifted by the bow handles and lowered into the water. And already in the water, the wheels are set to the swimming position.

Most inflatable boats produced today are quite heavy, especially those longer than 3 meters. We're talking about boats that are originally designed to be powered by an outboard motor. Their design necessarily includes a transom. Launching such a boat on the water alone is quite problematic. There are two ways out: always take another assistant person with you when fishing or hunting, or install it on transom wheels. We like the second option much better.

All wheels must have two positions: for transportation and for swimming. The dimensions of the wheels and their racks do not exceed the dimensions of the transom and do not affect movement in any way or create any resistance in the water. It only takes a few minutes to install the transport wheels. After bringing the wheels into the desired position, the motor is installed in its place, the boat is lifted by the bow handles and lowered into the water. And already in the water, the wheels are set to the swimming position.

The folding wheels simply retract into a certain position, and then just as easily occupy another desired position. And all this is done literally in one movement. It is clear that in this case the reliability of the mechanism plays an important role.

The choice largely depends on the ground on which the boat will move. For sand you need wider wheels, and for rocky shores narrower ones. This is the only way to ensure their sustainability.

Tips for a fisherman: Which motor to choose for a two-seater rubber boat - Tips for a beginner

Transom wheels for a boat can be of several types. Firstly, they can be folding or removable. The second option means that after the end of the boat’s use, such wheels are removed. They are a little cheaper, but you will have to reinstall them each time. This does not take much time, but still creates some discomfort. When purchasing them, be sure to pay attention to the fact that the kit includes all the necessary mounting materials.

The folding wheels simply retract into a certain position, and then just as easily occupy another desired position. And all this is done literally in one movement. It is clear that in this case the reliability of the mechanism plays an important role.

In addition, manufacturers produce dual transom wheels designed for boats with powerful (and therefore heavy) engines. For boats with an inflatable bottom, experts recommend purchasing transom wheels on an extended stand.

Below are reviews from anglers sharing their experience of installing wheels on PVC boats:

Functions of transom wheels

The main purpose of having transom wheels comes down to:

- Simplifying the process of delivering a boat from land to water.

- Mobility of PVC boats, especially on land.

If the boat is equipped with a motor, then it is quite difficult for one person to move it. It’s not so much difficult as it is inconvenient due to its significant dimensions. The task is greatly simplified if two people fish together. If this is not possible, then transom wheels will help.

Their presence makes the fishing process especially interesting and effective. With the help of a boat, there is every chance to fish in places that cannot be reached from the shore. As a rule, fishing with a boat always means productive fishing and, as a result, a great mood.

The name of the wheels comes from the place where they are mounted - which is the transom. The transom is the rigid part of an inflatable boat where the motor is mounted. Thanks to the presence of transom wheels, one person, without assistance, will be able to move the PVC boat without much effort along the shore, as well as lower it into the water and pull it out of the water.

The main task is to securely and correctly fasten the device so that it does not fail during fishing.

Advantages and disadvantages of having transom wheels

Transom wheels installed on a PVC boat have a number of advantages. For example:

- Additional conveniences appear during operation.

- The boat acquires new technical qualities.

- The functionality of the watercraft increases.

- Transom wheels take up little space.

- Valuable time associated with moving the boat is saved.

- The mobility of the product increases.

- Simplicity of device and mounting.

- The presence of wheels does not affect the handling of the boat.

- Additional service life of the device.

The disadvantages of their presence include:

- If you buy them, they are expensive.

Making such a useful device yourself will help solve this drawback.

Advantages and disadvantages of making a mobile device yourself

The advantage of making a transom transport device yourself is that you can save money on purchasing factory options. In addition, improvised materials are used for useful purposes, which no one seems to need, but it would be a shame to throw them away. Also, making a chassis yourself is a fascinating process in which family members and friends don’t mind participating.

The disadvantages of homemade boat wheels are that the design is often unreliable. Common omissions: shoddy welding, old scrap materials, incorrect hole placement, weak locking mechanism.

To independently create a reliable chassis design for a PVC boat using available materials is not an easy task, but it is doable. Especially when there is a lot of blank material at hand.

However, to save time and be confident in the reliability of the design, experienced fishermen still advise using the factory kit so that the boat does not let the fisherman down at the most inopportune moment.

Types of transom wheels

Manufacturers produce several types of transport chassis. Here are the main ones.

Transformer KT-5

This model has its own installation specifics. The chassis is attached to the transom in such a way that they can not be removed when transporting the boat in a folded state. This design has additional advantages related to ease of movement. When moving on water, they do not affect its maneuverability.

This chassis model allows one person to move the boat from place to place without much effort.

The main material of construction is steel, 3 mm thick. A profile pipe of a special configuration is used as wheel stands. This allows you to quickly install the device and transfer it from the transport position to the working position.

In addition, the wheels have a spring mechanism that allows you to transport the boat over uneven surfaces.

Automatic KT-3N and KT-3NU

The main material for the manufacture of such devices is stainless steel. Models are intended for inflatable boats with a rigidly fixed transom or for boats that have a rigid hull.

Advantages of automatic fixation:

- The device is made at a high technical level.

- Has high reliability.

- Features a modern design.

- Can serve as the best option when moving a boat over long distances.

- Easy to use.

In the production of automatic CT devices, laser cutting is used followed by argon welding. The result is high accuracy, excellent quality and acceptable appearance.

These wheels can support a loaded craft weighing up to 120 kg.

Folding transom wheels

The device is mounted on the outside of the transom, which allows you to easily fold the wheels from bottom to top. To fix the product, the design uses springs, which are located inside the racks and are made of stainless steel. It should be noted that the remaining parts of the folding wheels are made of stainless steel, which provides the structure with enviable strength and resistance to both fresh water (KS-03) and salt water (KS-04).

Advantages of this model:

- Easy to install, remove and operate.

- There is no need for constant removal and installation of the chassis.

- The fastening method does not interfere with the control of the vessel.

- There are packaging options available with the wheels installed. Can be installed on any model of PVC boat. Withstands loads up to 180 kg.

Swivel chassis, for PVC boats

Such designs are aimed at transporting a boat by one person over short distances. They are installed using 4 bolts to a transom made of plywood. It is possible to adjust the height of their installation due to the length of the mounting pin.

To remove the device, simply unscrew the nut, which is located on the side of the rack. The wheels are designed to move weights up to 140 kg.

The main parts are made of stainless steel, which indicates the durability of the product.

Chassis types

1. Fitting the chassis to the transom. The chassis should not catch the cylinder and the bottom of the bottom. Place the landing gear against the transom and lift - they should rise and fall without touching the PVC.

2. Place the chassis pad as shown below and mark the places for drilling:

3. We carry out drilling, placing the same PVC or wood board on the back side of the transom so that chips do not form on the transom. We recommend using high-quality drills with a drilling length limiter.

4. Having drilled the grooves for the bolts on one side, we also carefully drill holes on the other side, in the opposite direction. After this, you can attach the pad and carefully, without overtightening, insert and lightly tighten the bolts - not completely, but for checking.

5. Duplicate the installation of the second platform on the other side of the transom. A ruler and square will help you accurately determine the installation location. After working with a drill, we collect plywood shavings with a vacuum cleaner, this is very convenient.

6. After making sure that the landing gear is seated correctly, remove them. Next, apply silicone to the holes for the bolts and a thin layer on the surface of the platform adjacent to the transom:

7. Re-insert the bolts (finally), remove the excess squeezed out sealant so that the connection looks beautiful. Place the washers and tighten the nuts included in the kit. We also recommend using thread locker to ensure maximum joint strength.

We evaluate the result - the boat is equipped with a convenient and very useful addition that will help you operate the boat with the help of one person. This is the job done!

• Take care of your health and boat

Installation of the chassis is justified on any, even the smallest boat (from 2.8 m). Not to mention large vessels (from 3.6 m), where this is rather a necessity.

There are many different accessories for inflatable boats. There are those that are purely for comfort - for example, linings on cans, and there are those that are out of necessity. The latter can easily include transom wheels. Thanks to them, you can move the boat along the shore over short distances with minimal physical effort.

Tips for fisherman: Spoons for vertical trolling from a boat - Detailed review

Disadvantages • How much do they cost? How many!? How many!?

Normal transom wheels cost from 4,000 rubles, good ones from 5,000 rubles. Everything, of course, is relative, since the price of a boat is 50,000, it doesn’t seem expensive, but if you paid 20,000 for a boat, then the price of the wheels seems inadequate. But these are realities and you have to take them into account - good wheels are worth the money.

What you can save on without harming yourself is by choosing a device for specific tasks, where the difference is not in materials, but in design. Transom wheels, designed for different loads (100 or 300 kg) and different boats (NDND. payolas), cost differently. The types of fasteners (quick-release, regular) also differ in cost.

But what you absolutely cannot skimp on is the materials: steel no less than 2.5 mm thick, wide tubeless wheels, bolts, washers, wings - everything so that you can tighten and unscrew it in any conditions without fear of “breaking it off”. On the water, even the smallest piece of iron is waiting for its moment to show its stubborn character.

• Retract the landing gear!

Owners of boats with wheels do not like to talk about this, but the situation when the landing gear was not retracted while moving is very common. You can travel a fair distance in this position in planing mode. With proper fastening and quality, such loads on equipment do not produce any consequences. Here the question concerns only your prestige and self-esteem, especially when the embarrassment occurs in public - humor and jokes cannot be avoided.

Raising the wheels when you move away from the shore and lowering them in advance when you dock is a matter of habit that is acquired over time; first you will have to practice.

But the raised wheels in the boat do not take up any space, since they hang behind the transom above the water. When controlling the motor, they also do not interfere in any of their positions, except that the speed decreases if they are not raised (see above).

Advantages • Easy to install

Everything is simple with the mounting points. On inflatable boats, the only place where you can fasten the wheels is the transom; it is rigid and the center of gravity passes through it, which ultimately allows you to roll a weight of 100-300 kg alone. Installing wheels yourself is simple, but it requires space (you need to pump up the boat), a tool with materials (drill, tape measure, keys, sealant) and time (10-20 minutes, not counting the assembly and disassembly of the boat itself). In services, this procedure costs from 600 rubles.

• Take care of your health and boat

Installation of the chassis is justified on any, even the smallest boat (from 2.8 m). Not to mention large vessels (from 3.6 m), where this is rather a necessity.

Firstly, wheels will keep you healthy; a torn back has never made anyone want to repeat the “pleasure”. With wheels, even “unbearable” weights can be quickly moved over short distances with minimal strain on the muscles and back.

Secondly, the boat will be more intact, its service life will increase, since contact of the stern with stones and sand is eliminated at the moment when you pull the boat out. This is especially true for the bottom in the transom area, the load on this part is maximum, the protection (if there is one) and the PVC fabric wear out over time, moisture penetrates into the transom and it rots, the seams come unglued, and replacing the transom is the most expensive service in the service. and you won’t do it yourself.

• New opportunities

Transom wheels provide additional mobility. Let's say you have a set: 3.6 m boat + 10 (15) hp motor. It’s hard to handle this alone on the shore, but if you have wheels installed, then you can go fishing at any time without a partner. And, of course, this is comfort, but comfort with benefits, once you try it there will be no doubts.

Tips for fisherman: Fishing rod for sea fishing from a boat - All the nuances

Author: Alexey Lazarev Important: Publication of material is permissible only if there is a direct indexed link to the source

The wheel material is selected depending on the aggressiveness of the water of the reservoir in which the boat with NDND will be operated. For use in seawater, stainless steel models are better suited. Any other material will quickly become unusable even with minor damage to their surface.

Making transom wheels with your own hands

The size of the structure must match the size of the boat. The main task is to ensure that the chassis does not interfere with the maneuverability of the craft.

For manufacturing it is necessary to prepare the following materials and tools:

- A pair of wheels with a diameter of 350 mm and a width of 60-80 mm.

- Profile pipe, cross section 25x25 mm, made of stainless steel.

- A pipe of suitable thickness for mounting the wheels.

- Fasteners: nuts, bolts, washers, etc.

- A hacksaw, electric drill, grinder, wrenches, pliers, etc.

Manufacturing stages:

- The installation location on the transom of a square profile is determined (so as not to interfere with the operation of the engine).

- Measure the distance down, paying attention to the fact that the wheels should be installed just below the lower edge of the transom, taking the radius of the wheels as a basis and adding 5 cm. This is the most optimal arrangement of the wheels, which will not affect the running capabilities of the craft.

- The bracket where the wheels are mounted can be made either at a right angle or at another angle. A right angle bracket is most preferable since its installation takes minimal time. In addition, this element is able to withstand heavy loads.

The second option is more technologically advanced, but also more optimal, since the wheels are placed under the bottom of the boat and do not interfere with the operation of the outboard motor.

To do this, 4 sections of the required length are sawn off from the profile and, using welding, they are attached to the bottom of the profile. A through hole should be drilled in the tubes so that the rings can be fixed. In addition, a nut of the required diameter is welded to the inside of the tube ring so that the product is not pressed against the fastener.

It is better to install plastic or rubber plugs on the outside to prevent water from getting inside.

In the upper part, 2 through holes should be drilled, which are provided for mounting the chassis to the transom.

The two parts of the fastening are welded together. The angle between them can be 35-45 degrees, otherwise the ends are adjusted.

After this, once all the preparatory work has been completed, the chassis is installed on the tubes and clamped with nuts and washers. So, the device is ready for use. If necessary, the structure can be painted. If the material is stainless steel, then this is not necessary.

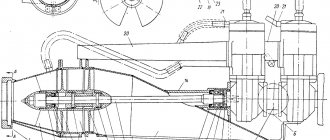

Drawing

Design elements

Mounting methods

Several mounting options are possible. In this case, you should adhere to some recommendations, such as:

- The mount is placed on the transom and marks are made along the holes with a pencil. After this, holes of the required diameter are drilled strictly in the center.

- The following steps are similar, but holes are drilled on a sheet of durable material such as textolite, aluminum or duralumin. This sheet is applied to the inside of the transom and the holes are marked with a pencil, as in the previous case.

- It is better to install the bolts on the inside of the boat so that the nuts are on the outside.

- The wheels are secured with bolts, nuts and washers.

Some recommendations:

- For ease of transportation, it is advisable to use transom wheels.

- The finished product costs a lot of (comparatively) money, so the best option is to make the chassis yourself. Firstly, it's inexpensive, and secondly, it's interesting.

- All fasteners and parts of the device must be made of stainless steel. But this is the ideal option. If this is not possible, then it can be made from ordinary metal, but then you will have to carefully coat the structure with paint or waterproof varnish.

- The transom wheels should be installed very carefully so as not to damage the boat itself. After all, this is a very expensive thing that will then have to be repaired.