Preparations for repairs

Before you begin repairing an inflatable boat, you need to complete a number of preparatory work. You need to place a stone, board or other flat object under the hole. The base must be strong. The air is released from the chambers, the surface is cleaned and degreased with toluene, gasoline or alcohol. It is not recommended to use acetone; it will damage the PVC. Emery and sandpaper will also make the holes even larger.

The patch is cut out. It is made from the same material from which the boat is made. It is better to use a repair kit that contains everything you need for the job. The patch is cut in such a size that its edges extend 2 cm beyond the hole. Its shape is square, round, oval or rectangular. Before gluing, the patch is cleaned and degreased.

Repair kit

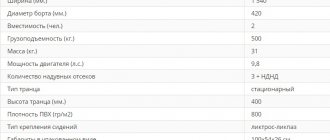

The boat is supplied with a repair kit, along with oars and a pump, designed to repair damage. It includes patches of different colors made of PVC:

- large patch - 1 pc.;

- round patches - 4 pcs.;

- glue in a tube.

The glue may be of poor quality, then you will have to purchase another one.

Criteria for choosing adhesive

- If the price of glue is below average, most likely you have a low-quality product that is not capable of gluing firmly and reliably.

- You cannot buy cyanoacrylate-based mixtures like superglue or its analogues. The connection will be strong, but short-lived.

- Boat glue should not stick to the skin, otherwise it is of poor quality.

- Use a special mixture for inflatable boats, not a universal mixture.

- For gluing, choose mixtures that are resistant to temperature changes and prolonged contact with water.

- The best glue for minor repairs is liquid patch.

- To partially replace large areas of PVC or restore the surface of a boat, it is better to use two-component compounds. They are also used for permanent boat repairs.

- Boat fittings are repaired with one-component adhesives.

- When swimming, choose prepackaged glue in small tubes.

What glue to use

The most important thing in repairing punctures is to know exactly how to seal a rubber boat and how to connect the patch to the boat material. The reliability of the repair depends on the quality of the adhesive mixture. What kind of glue can you use if the repair kit contains low quality or has run out? The popular composition “Secunda” is not capable of sealing a hole in a PVC product efficiently. The patch will stick, but will soon fall off. The composition of this glue is cyanoacrylate, which widens the hole.

Experienced fishermen know well what glue to use to glue a PVC boat at home. It is better to use a polyurethane-based adhesive; such a tube is included in the repair kit. This may be “Professional” glue, but it is selected specifically for PVC products. The quality of the glue is determined by the following criterion: a good composition does not stick to your hands when it dries. Once dry, excess cannot be removed from surfaces. Heat resistance is also of great importance; the boat gets very hot in the sun.

When choosing the right composition, you should consider the following:

- special glue is better than universal glue;

- cheap composition is of low quality;

- superglue is not suitable for working with PVC;

- polyurethane composition requires heating to 70 °C.

If the listed factors are taken into account, the gluing will be of high quality.

Gluing methods

There are several rules for how to seal a PVC boat or carry out other repairs on rubber boats with your own hands. After cleaning and degreasing the parts to be glued, you need to give them time to dry. The glue is applied to the damaged area and to the patch in a thick layer. After application, it dries within 5-7 minutes. The exact time is indicated on the packaging. The operation is repeated 2 more times. After the third drying, the patch is applied to the damaged area, pressed and smoothed. For smoothing, use a rolling pin, bottle or other round object.

The trick to the job is heating the repair area. If it is done at home, it is better to use a hairdryer. In nature, a mug of heated water is used. After heating, the repair area cools and dries. You can use the boat after 2-3 hours, but even better - after 2-3 days. By this time the glue is gaining strength.

In this way, it is easy to repair cuts or punctures up to 5 cm. Sometimes an underwater snag pulls out a large piece from the bottom, then it is easier to turn to specialists for help. Such repairs are carried out in workshops that carry out tire fitting. You can also seal a puncture in a swimming mattress there.

What will you need for the job?

To repair a watercraft at home or on shore, a craftsman needs to acquire the following tools and consumables:

- A construction knife or scissors.

- Pencil or marker.

- Hairdryer or burner. If repair work is carried out in field conditions, then you can heat the patch using a regular lighter. A hot water bottle will also work for this purpose.

- With a small brush. It will be used to apply glue to the damaged area.

- Soap and a piece of rag.

- Solvent.

- Glue.

The repair kit that comes with the boat should contain a set of ready-made PVC patches in the amount of 6 pieces with a diameter of 4, 6 and 8 cm, as well as a special tube of glue.

How to make repairs

Repairing a PVC boat with your own hands should be carried out taking into account some features:

- PVC is a durable material, it is not affected by ultraviolet radiation, salt water and petroleum products;

- product service life - 20 years;

- has high wear resistance;

- is not afraid of mold, dampness, does not rot and does not rot;

- withstands temperature changes from 40 degrees below zero to 50 degrees above zero;

- weighs less than rubber counterparts.

Repair and tuning of PVC boats step by step looks like this:

- the area for the glue is cleared;

- degreased;

- the patch is cut out;

- the adhesive is applied and dried;

- a second layer is applied and dried;

- a third layer is applied, dried and applied to the damaged area;

- the surfaces to be glued are heated to 70 °C;

- the surface is leveled using a roller.

After 2-3 days, the patch will be firmly fixed in place.

Punctures, burns

Punctures and burns happen far from home. Emergency and permanent repairs can be performed. Emergency repairs are used when it is necessary to continue fishing from a boat. Procedure:

- the punctured chamber descends;

- the patch is cut out;

- the surfaces at the site of damage and patch are cleaned and degreased;

- apply a layer of glue and dry for 2-3 minutes;

- the patch is pressed against the hole.

This method allows you to stay afloat for some time, but the house needs to be constantly repaired. If you have free time:

- the damaged chamber is lowered and the puncture site is degreased;

- the patch is cut out and degreased;

- The adhesive mass is applied to the surface and dries for 15 minutes;

- a second layer is applied and allowed to dry for 15 minutes;

- apply the third layer and dry for 7-10 minutes;

- the patch is applied to the hole and heated with a lighter or a mug of water;

- the hot patch is rolled with a bottle to remove air.

After 3 hours the boat can be pumped up, but not to the maximum. The glue will dry completely after 3 days.

Large punctures

Special knowledge is needed when solving questions like how to glue a boat that is torn at the seam, or a large puncture, or whether it is possible to replace a valve on a PVC boat with your own hands. Sealing holes larger than 4-5 cm is done using the same methods as small punctures. The only difference is in the number of patches, which need to be used 2 or more: 1 patch is applied from the inside, the other from the outside. They roll well. The strength of adhesion is checked with a soap solution, which is applied to places where air can pass through (soap bubbles will appear at the exit point).

A large hole makes it difficult to join the edges of the material. In such cases proceed as follows:

- the damaged area is washed, dried and degreased;

- the edges of the hole are sewn together with harsh threads;

- glued with 2 patches;

- A larger patch is placed on top of the glued one.

It is better to have large holes repaired in a workshop; they have equipment, materials and craftsmen there.

Sometimes the valve fails. The boat valve is not repaired, it is simply replaced. To perform the replacement, you need to take the key from the repair kit and unscrew the tap. If you don't have a key, it can be easily done using a plastic pipe and a jigsaw. The valve is tightened with the same key. Replacing a valve on a PVC boat in a workshop costs 600 rubles.

Bottom cuts and torn holes

If punctures and lacerations are easily repaired, then restoring the bottom will not cause problems for a master who has experience and knows exactly how to seal PVC with a damaged bottom. Therefore, it is better to repair the bottom in a workshop, otherwise the glued rubber may come off at the most inopportune time. Repairing a rubber boat with your own hands is not that difficult. Good gluing techniques, fabric and glue must be used. Holes up to 10 cm can be sealed at home.

The best patches are made from PVC. They are glued on the bottom and top of the bottom. The gluing areas are cleaned and degreased. Other larger ones are glued on top of the patches. With proper operation, the boat will last for many years after repair, if it is washed, cleaned and dried after each use.

III. Damage repair

In fact, all types of damage to PVC boats are eliminated using the same method, with only a slight difference.

Step 1. Stripping

We clean the gluing area from dirt. Some people recommend using fine sandpaper for sanding, but this can only damage the surface. Sandpaper erases the coating of a boat just like everything else, and this is not exactly something that will improve the quality and durability of the boat. So, unless absolutely necessary, you should not resort to such a drastic method, unless the pollution is very firmly rooted and there is no other way to get rid of it.

Step 2. Degreasing

For ideal and durable adhesion, the surface must be degreased. The ideal solution for this is a solvent; you can also use acetone. If there is neither one nor the other, then alcohol will do, but this is only as a last resort. When degreasing the boat, you need to be careful and not overdo it - solvents, although hard, corrode the surface of the boat. Therefore, everything should be in moderation.

Step 3. Preparation

· Cut out the patch. It should be a couple of centimeters larger than the hole.

· Apply it to the damage and trace the contours with a pencil.

· Lubricate the patch itself and the gluing area on the boat with glue.

· Let the glue dry for 10 minutes.

· Then again apply a layer of glue to the patch and the surface of the boat.

· Wait a few minutes. The glue should dry a little, but set.

Step 4: Gluing

· Using a hair dryer, heat both surfaces coated with glue. You need to do this quickly so that the surface warms up, but the glue does not dry out.

· We apply the patch to the surface, making sure that it lies strictly along its contours drawn and smeared with glue, and also that there is no air between the surfaces to be glued.

· We thoroughly roll the gluing area with a hard roller or some similar object so that the surfaces adhere well.

· We send the boat to dry for 2-3 days.

Minor scratches

which only exposed the material, simply fill it with glue. But you can, just to be sure, put a patch on it.

For damage greater than 5 cm

two patches are installed. One is outside, the other is inside. First you need to glue the one that will be inside, then the outside one.

Damage exceeding 15 cm

should be eliminated by specialists; it is difficult to do it yourself. And the repair kit is not designed for such serious holes - there is not enough material.

Boat preparation

Before repairing, you need to find the hole; it is worth remembering that there may be several damages. Punctures are not always noticeable. Therefore, the inflated boat must be inspected in the water. When holes are found, you need to circle them with a marker or something else so as not to repeat the search procedure.

Then the boat descends. No glue will hold the patch when air whistles out from under it. You need to place a flat object under the damaged area: a board, container, stone, etc., whatever is at hand. The base should not sag when pressed.

Before sealing a PVC boat, you need to clean it from dirt and degrease it. To do this, you can use gasoline, toluene, thinner, alcohol or vodka. Acetone can damage PVC, so its use is not recommended. You cannot use sandpaper or anything like that, because... It's easy to damage the boat and make the holes bigger. The degreaser must completely evaporate from the surface. Only in this case can you start gluing.

Features of use

The main tenets are not to get caught when casting with hooks, not to be damaged by an accidental shot, not to be launched into the water in unexplored places so as not to tear the bottom, not to swim into snags and reeds, to raise the engine in shallow water so as not to tear off the transom, probably you can lower it. Everyone knows this, but not everyone adheres to it in the excitement of hunting or fishing.

Let's look at the moments before and after launching:

- Tip #1. When inflating the boat, it is advisable not to overdo it; excessive pressure in the cylinders in the sun can lead to their rupture along the seam or in the place where the valve is installed.

- Tip #3. Although PVC material is not afraid of moisture, during short-term storage, drying after washing the boat is welcome.

A separate topic is preparation for winter (long-term storage) and ways to keep an inflatable boat without damage until the next season:

- First of all, it is advisable to thoroughly wash the boat with soapy water, removing fish scales, mucus, algae and other dirt; if the transom is removable, then remove it and store it separately.

- Many people advise storing it in an inflated state during the off-season, but this is an anachronism, a habit passed down from the past, when there were only rubber boats. Polyvinyl chloride perfectly tolerates temperature changes, withstanding -40ºС in winter +70ºС in summer.

- When storing in sub-zero temperatures, it is enough to carefully put the boat in a bag and if it is in the garage, try to find a place to store it that is inaccessible to rodents.

The only advice is to try to protect the packaged boat from various influences in the cold, in other words, “do not tilt” the entire storage period.