Reel Maintenance

As a rule, a new spinning reel has a pleasant velvety stroke, smooth and silent rotation. But after prolonged use, some crunching, rustling and vibration appear in the mechanism. To get rid of or prevent this, it is necessary to periodically disassemble the coil, clean it of dirt and change the lubricant.

High-quality lubrication of the reel makes the operation of the reel smooth and pleasant; moreover, the new lubricant extends the service life of all mechanisms.

Maintenance of the coil should be done periodically, several times a season, depending on the frequency of use. And once a year you need to completely disassemble the coil and replace the lubricant.

Naturally, you need to constantly monitor the reel, do not drop it on hard surfaces, try to avoid water getting into the mechanism and try to avoid all kinds of contamination.

When should you lubricate your spinning reel?

Spinning reels have a complex mechanism that requires proper care. There are gears inside the reel, which can become clogged during fishing or rust when exposed to moisture. Which ultimately leads to malfunction of the device. In such cases, lubrication is necessary for further use.

Lubrication is also necessary in the following cases:

- when the device has been in the water for some time;

- the product was in sand or soil;

- if the coil does not work well;

- in the absence of the necessary noise when using the coil;

- if interference and extraneous sounds are felt when scrolling the coil;

- before the start of the fishing season, if the product has not been used for a long time.

Let's celebrate! Also, the lubrication procedure can be carried out at any time when the fisherman deems it necessary; an additional procedure will facilitate the process of using the product. It should also be noted that the procedure for applying lubricant is quite labor-intensive and requires a lot of time and care.

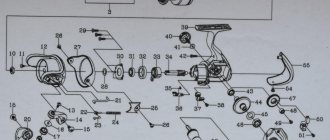

How to disassemble a spinning reel

When disassembling a spinning reel, lay out all its parts in order from right to left, this will allow you to quickly and correctly assemble the reel.

Carefully remember the position and installation order of all parts, follow the following instructions.

Reel disassembly steps:

- Remove the friction brake nut;

- Remove the spool;

- Remove the washers and gears on the rod;

- Unscrew the handle;

- We disassemble the coil mechanism: unscrew the bolt securing the nut.

- Carefully unscrew the rotor clamping nut with a wrench or pliers;

- Removing the rotor

- We remove the line-laying arm and the mechanism that locks it from the rotor.

- We disassemble the line roller (unscrew it with a screwdriver);

- Unscrew the bolts and plugs on the cover and remove the cover.

- Inside the coil you will see two gears and a slider - this is the main mechanism.

- Next, you need to remove the rod, after unscrewing the bolt that secures it.

- Remove the main gear, small gear and other parts.

- To remove the pinion gear, unscrew the three bolts.

- Remove the bearing from the pinion gear.

- Remove the cylinder from the pinion gear.

Reel disassembly is complete!

See video below for disassembly and assembly.

Reassembling the coil is carried out in the reverse order.

How to lubricate a spinning reel?

In order to lubricate a spinning reel, you need to prepare all the necessary materials and disassemble the device.

How to prepare for the process?

Properly organized work will not only speed up the process, but also prevent possible failures.

Before you start lubricating the coil, you should prepare the following materials:

- lubricant;

- soft fabric, small piece;

- screwdrivers;

- tweezers;

- wrench;

- brush for applying the substance to small parts.

Let's celebrate! In some cases, additional tools may be required to apply the lubricant.

Algorithm of actions for lubrication

To comfortably lubricate fishing gear, you must perform the following algorithm of actions:

1. Prepare a horizontal surface and conveniently place all the tools.

2. To disassemble the coil, to do this you need to:

- unscrew the handle and release the spool;

- remove the bushing;

- unscrew the retaining flange and remove the rotor;

- unscrew the bolts from the overrunning clutch and remove it;

- unscrew the bolt and remove the mechanism cover;

- remove the gears, but before removing them, mark their position and sequence with a marker. This is necessary for the correct installation of parts;

- Using tweezers, remove the stopper;

- Unscrew the bolt that secures the carriage to the axle and remove it;

- remove the axle.

- remove the part called the “worm”;

3. Wash all components in gasoline and lay them out on cloth in sequential rotation for convenient further collection of the coil.

4. Dry with a hair dryer;

5. Using a soft cloth and brushes, clean the upper parts of the reel. For convenience, you can use a small wooden stick, which is wrapped in cloth, and clean the part.

6. Reassemble in the reverse order, with each part lubricated with a special product.

7. Check the correct operation of the fishing tackle.

Let's celebrate! Beginners will need to mark the parts during the process, as reassembling may cause problems. Instead of marks, you can use photographing of individual parts. During the lubrication process, you should not rush and check every detail in detail; incorrectly installed components can lead to damage to the coil and further unsuitability of the product.

Spinning reel lubrication

- Clean the surface of the coil.

- Disassemble the coil.

- Clean parts in gasoline.

- Lubricate parts and bearings.

- Assembling the reel.

Grease is used to lubricate gears and parts. Liquid lubricant is used to lubricate the bearings.

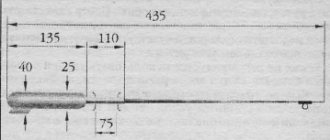

The teeth of all gears must be lubricated so that the grease completely fills the space between the teeth. Excess grease must be removed. Grease the large gear, the pinion gear, the small gear, the internal part on the small gear, and the rod.

A thin layer of thick lubricant can be used to coat other metal parts to prevent them from corroding. Open type bearings are lubricated with liquid lubricant, while closed type bearings do not need to be lubricated.

During assembly, the pin of the small gear should fit into the groove of the part covering it. The main gear needs to be lubricated in several places and installed in the reel body. Next, lubricate the rod along its entire length with thick lubricant and install it in place. The main reel mechanism is lubricated!

Reassembling the coil is carried out strictly in reverse order!

Is it possible to lubricate the coil without disassembling it?

In order to lubricate the product without preliminary disassembly, it is necessary to use silicone lubricant, which is produced in liquid form and is available in cylinders with a convenient dispenser. Using a thin dispenser, the required amount of lubricant is introduced and the product is rotated.

However, it should be noted that this lubrication method cannot be used for a long time. In order for the product to function fully, it is necessary to disassemble the fishing product and lubricate each part.

Spinning reels most often have a long service life, however, in order for the reel to work without interruption, it is necessary to properly care for it.

To carry out the correct lubricant application process, the following tips must be followed:

- arrange all the details in order;

- carefully remove residual old lubricant;

- Do not apply lubricant in large quantities, as this may damage parts.

Note! Compliance with timely care, as well as simple rules for storing fishing tackle, will allow you to use the reel for a long time without reducing its basic functions.

Reel Lubricant

Do not use grease as a thick lubricant.

Use specialized thick and liquid lubricants for reels. On sale you can find lubricants for reels from specialized fishing companies: Abu Garcia, Daiwa, Shimano, Ryobi, Tica, Mikado, SFT, etc.

It is better to use lubricant from the same company that manufactured the reel.

For example, Shimano produces a special grease designed for the main pair, mechanisms and bearings. Its viscous structure reduces friction, increases reel life and makes reel operation smoother.

The price of reel lubricants ranges from $2 to $100, depending on the brand and volume.

How to lubricate a reel, lubricant manufacturers

All types of lubricants can be divided into the following types:

- Branded lubricants recommended by manufacturers of fishing products. Most often produced in the form of a spray.

- Domestic lubricants are frost-resistant and do not damage rubber parts.

- Silicone lubricants are water-repellent and are used for various types of fish products.

Note! The type of lubricant can also be thick, liquid or universal; each type of lubricant can have its own advantages and disadvantages.

Grease

The use of thick lubricant allows you to properly lubricate all parts of the gear. In addition, the thick type of lubricant does not drain and protects the product from possible contamination for a long time.

You can use the following lubricant companies:

- Reel Grasso silicone;

- Okuma;

- Abu Garcia Precision Grease;

- Shimano DG01.

When using thick lubricant, it is necessary to disassemble the product and lubricate each component separately.

Note! Most commonly used for bearings and gears. The disadvantage of thick lubricant is that small parts are often lubricated in large quantities, which leads to improper operation of the product.

Liquid lubricant

It can penetrate into the farthest parts of fishing gear, the lubricant is in the product and does not leave it, while constantly circulating, lubricating the component parts. Most often, liquid lubricants are produced in the form of a spray with a convenient tip.

The following types can be used:

- Hedgehog Studio Alchemy Oil Medium Light;

- Abu Garcia Reel Oil;

- Daiwa Reel Oil 2.

Let's celebrate! Most often, a liquid type of lubricant is used for rotating elements and bearings. Can be used for both conventional gear and reels used for offshore fishing.

Multi-purpose lubricant

Used to completely lubricate the product. It has a medium consistency and is considered the most suitable type of lubricant for spinning reels.

The following lubricants can be used:

- Penn Pack Oil&Grease;

- Shimano DG09.

Universal lubricant is most often used for reels that are frequently used and exposed to various external factors.

Let's celebrate! Experts recommend using universal types of lubricants because the material is moisture-repellent and has the necessary degree of protection of the device from frost.